Faced with a variety of subslab problems, environmental managers are turning to horizontal drilling technology at a growing number of commercial building sites across the United States.

Engineered environmental horizontal well screens can achieve multiple objectives, including:

Vadose zone source removal,

Reduction of soil gas concentrations,

Subslab depressurization, and

Soil moisture control

Vapor mitigation and soil source removal represent the primary concern at environmental sites where volatilization of hydrocarbons at the water table or in the vadose zone can affect indoor air quality. At other sites, the main objective of subslab air removal is dehumidification to address moisture-related problems in the building floor. One such site is an office building in Raritan, New Jersey in which the building floor had chronic problems with wet spots in the floor that were caused by excessive moisture buildup in the subslab soils.

The Environmental Horizontal Well Screen System

The 100-by-300-foot office building was built on compacted sand backfill. Utility line depths and water table fluctuations indicated an optimal depth range for a horizontal extraction well screen between 1 ½ and 3 ¼ feet below the base of the building slab. A vertical soil vapor extraction (SVE) well pilot test provided the vacuum and flow rate range for the system, but the zone of influence of the horizontal well screen was estimated based on Directional Technologies’ data and experience from horizontal SVE wells installed and operated during the last 20 years. Based on these considerations, Directional Technologies installed one 300-foot long, 3-inch diameter polyvinyl chloride (PVC) horizontal well screen within a few feet of the centerline of the rectangular building. The horizontal well screen was placed mostly in the depth range of 1.6 to 1.8 feet below the slab, or 2.6 to 2.8 feet below the building floor. Directional Technologies was careful to maintain the client-required 12-inch clearance above a 6-inch diameter sewer line, and was able to respond to real-time directives from the building owner during the drilling operation to maintain varying preferred depths below different rooms of the building depending on footer and electrical conduit bank locations.

Directional Technologies completed the horizontal well screen installation in two days, and office workers in the building were able to work continuously without interruption throughout the remedial construction.

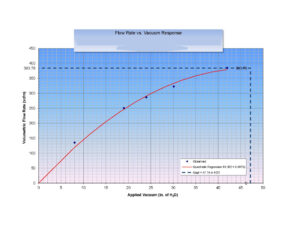

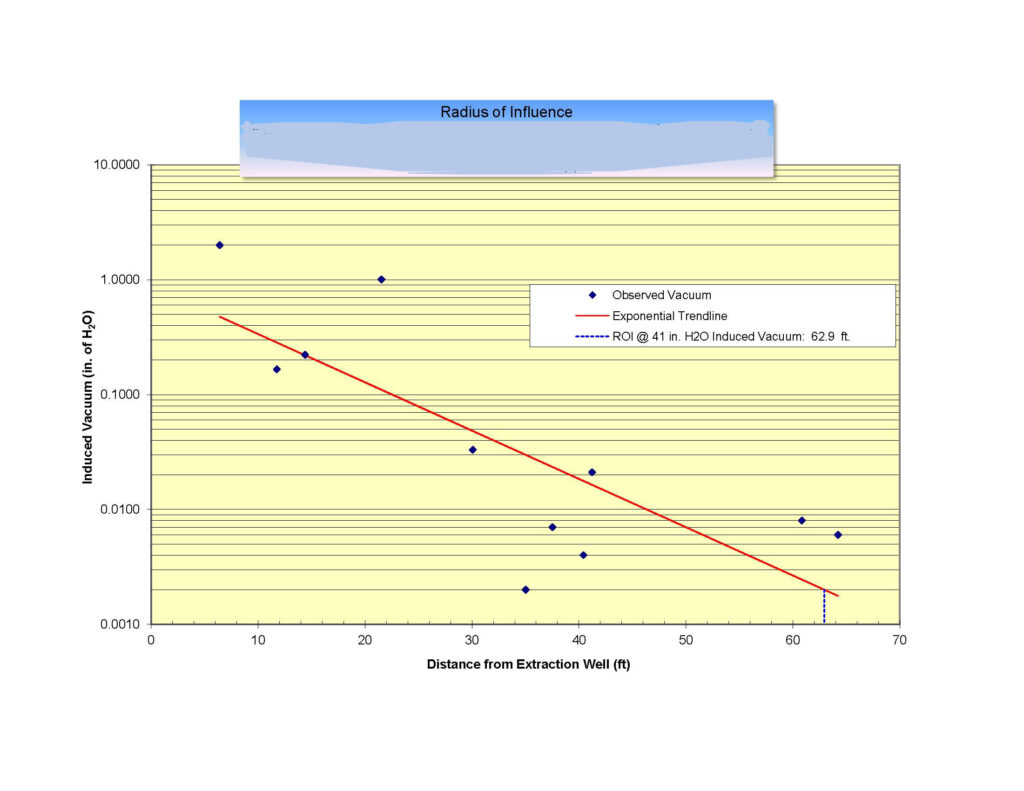

Performance Test

Vacuum monitoring points were installed at distances ranging from 6 to 64 feet on either side of the horizontal well screen. The zone of influence of the horizontal well screen was measured during a performance test with the horizontal well operating at varying pressures, increasing stepwise from about 10 to 40 inches of water. The test revealed optimal flow between 1 and 1.5 standard cubic feet per minute (scfm) per foot of screen. The horizontal well screen induced a vacuum in the compacted backfill that was measurable at monitoring points up to 63 feet away from the horizontal well, thereby creating a zone of influence essentially covering the entire subslab area of the building. The moisture-laden areas beneath the slab exhibited a reduction in relative humidity from above 95 percent before the horoizontal well began operating, to below 70 percent after the performance test. Engineered slot distribution provided by Directional Technologies ensured that vacuum was evenly distributed in the subslab soils along the entire 300-foot long horizontal well screen.

Conclusion

Shallow horizontal extraction wells installed beneath commercial building slabs are becoming an important tool for environmental managers tasked with achieving regulatory site closure with solutions to multiple problems, including groundwater and soil contamination, soil and building slab moisture, and vapor intrusion concerns. Horizontal extraction wells provide efficient installation techniques that avoid disruption of ongoing business, ease the burden of installation, and coupled with engineered well screens enable operation at vacuum levels and flow rates that allow efficient long-term operation of the horizontal remediation/mitigation system.