Horizontal Remediation Well System system technology was challenged on an In Situ Chemical Oxidation (ISCO) project. The impacts encompassed the approximate size of a football field. The rough dimensions were 300 feet long and 160 feet wide with several underground utilities.

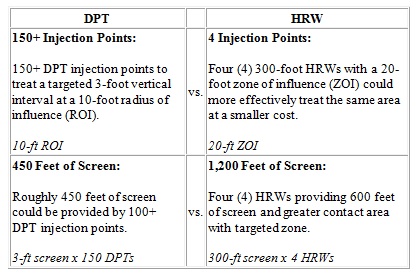

The main challenger was vertical injections with direct-push technology (DPT). The strengths and weaknesses of each technology were evaluated. Some of the highlights are as follows:

Vertical Well System versus Horizontal Remediation Well System

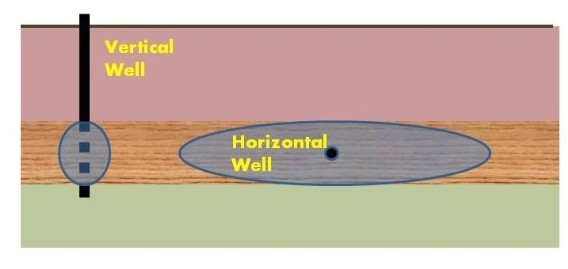

At first, a Horizontal Remediation Well system has a zone of influence (ZOI) that resembles a cigar-shape. Then the Horizontal Remediation Well system’s ZOI will gradually expand outward and into an elliptical shape. A Horizontal Remediation Well system’s ZOI is typically many times greater than a vertical well system in the same formation. (See the image of a cross section perpendicular to horizontal well below)

Cross Section of Horizontal Well vs. Vertical Well with ZOI

Besides creating over 150+ holes in the area resembling a football field, the DPT injection point layout would require offsets from underground utilities. More time would also be needed to hand clear 150+ DPT locations, whereas less time was necessary to hand clear 4 Horizontal Remediation Well locations for utility clearances. An option for a second ISCO event was also requested. This option required installation and abandonment of 150+ temporary points for DPT remedial approach. Whereas, the four (4) permanently installed horizontal wells were far more cost effective with little to no site restoration necessary.

Besides creating over 150+ holes in the area resembling a football field, the DPT injection point layout would require offsets from underground utilities. More time would also be needed to hand clear 150+ DPT locations, whereas less time was necessary to hand clear 4 Horizontal Remediation Well locations for utility clearances. An option for a second ISCO event was also requested. This option required installation and abandonment of 150+ temporary points for DPT remedial approach. Whereas, the four (4) permanently installed horizontal wells were far more cost effective with little to no site restoration necessary.

To summarize a winning strategy, a Horizontal Remediation Well system consistently outperforms a vertical well system. Horizontal Remediation Well technology provides an effective delivery method to reach previously inaccessible areas without disrupting the playing field.