Challenge

An environmental consultant engaged Directional Technologies to collect a series of discrete, soil samples beneath an electroplating shop using the firm’s horizontal drilling technology. The samples were to be analyzed by an environmental laboratory in advance of a site real estate transaction. The electroplating line covered an area of approximately 3,000 square feet, was heavily congested with equipment, the floor was covered with a thick (and very expensive) epoxy coating to contain liquid releases and the line runs “24/7.” The client forbade the penetration of the epoxy floor coating and would not interrupt electroplating line operations.

Solution

DTI’s senior horizontal drilling engineer and remediation technology expert met with the environmental consultant to discuss project goals prior to DTI mobilizing to the site. The agreed upon scope-of-work involved collecting as many sub-slab soil samples beneath the electroplating line as feasible during a one-day mobilization.

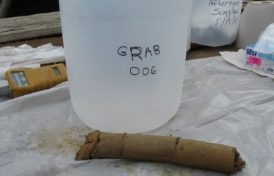

Directional Technologies mobilized to the site and advanced a horizontal bore approximately 30 feet beneath the electroplating line. DTI collected three discrete soil samples during bore advancement using a special sampling device. To collect soil samples, the driller withdraws the drilling tubulars, removes the drill bit, installs the sample, trips back into the bore, collects the sample, trips out the tubulars, reinstalls the drill bit, and then trips back into the bore. This is a time consuming process, but Directional Technologies was able to complete the first bore soil sampling process before noon, repeating the process in a second bore during the afternoon, collecting a total of six sub-slab soil samples in a one-day mobilization. Sample volumes were sufficient for the analytical suite selected by the consultant.