Introduction

Vapor Intrusion (VI) is a potential concern at any building; existing or planned, located near soil or groundwater contaminated with volatile organic compounds (VOCs). The usual mitigation method is to depressurize the slab, extract the vapors, and maintain negative pressure (vacuum) to ensure that any vapors migrating under the slab are captured and removed before they can enter the structure. Typically, a subsurface extraction well vapor mitigation system has the primary objectives of:

- Vadose zone source removal

- Soil moisture control

- Reduce soil gas concentrations

- Subslab depressurization

Horizontal Wells for Vapor Mitigation Installed Outside Building

Challenge

Regulators mandated groundwater and soil sampling beneath a pharmaceutical manufacturer’s building to address VI. Installation of vertical borings and wells was not feasible without disrupting manufacturing. Subsurface conditions beneath the building slab were unknown. Subslab soil and groundwater monitoring along with soil vapor extraction (SVE) for sub-slab depressurization (SSD) was completed with horizontal directional drilling (HDD) technology.

Approach

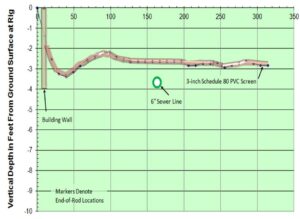

HDD technology was used to advance 2-inch PVC monitoring wells horizontally to a target depth of 20 feet below the building slab and 120 feet inside of the building wall. The horizontal wells served as compliance monitoring wells and were deployed outside the building with continuous well bores. Steering capabilities avoided rock fragments beneath the building to reach the target depth and length. As part of the vapor intrusion management program, horizontal SVE wells were strategically installed in the vadose zone and thin gravel layer beneath the building slab to actively mitigate vapors.

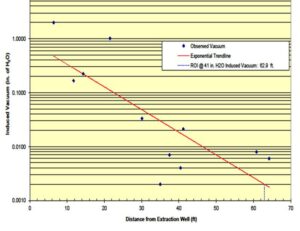

SVE Pilot Test: Radius of Influence (ROI) = 60 feet

Example: Horizontal Wells for Vapor Mitigation with 3-inch HDPE Installed Outside Building

Remedial Design: Horizontal versus Vertical

- In comparison to vertical vapor mitigation wells, horizontal vapor mitigation wells provide greater surface area for remediation

- Vertical vapor mitigation wells require significantly more site disruption. This includes core drilling floor slabs, conveyance piping in walls and ceilings, roof penetrations, displacement of tenants and loss or revenue due to disruptions

- Horizontal vapor miitgation wells avoid above disruptions

- Occupants as well as operations continue during installation of horizontal wells.

- Long screens with changing open areas in horizontal wells provide flexibility in balancing flow rate and vacuum levels for initial SVE operation and subsequent mitigation

Horizontal Subslab Screen Profile

Results

- Plume beneath the facility was actively mitigated

- VI Pathway and human health risk was eliminated

- Regulators approved No Further Action (NFA) for the site

The horizontal SVE and monitoring wells were advanced through a 6-inch concrete footer and through underlying rock beneath the building slab. To facilitate regulatory approval and acceptance, horizontal monitoring wells were drilled blind with no exit point to maintain similarities with vertical monitoring wells. The horizontal SVE well screens were designed to accommodate low vacuum requirements of typical vapor intrusion mitigation systems. Disruptions to the pharmaceutical manufacturer’s operations were avoided. Advancing the horizontal wells beneath the building effectively monitored and actively mitigated the source area to eliminate the VI pathway. The site obtained regulatory closure and no further action.

Performance Evaluation and Conclusion

- HRWs are an effective, non-obtrusive and economical method of remediating and removing soil vapors beneath existing buildings

- The effective ROI of HRWs is substantially greater than vertical wells

- Vapor intrusion prevention can be achieved even in situations where a shallow water table is present beneath the building

- Installation of HRWs does not interrupt ongoing operations of a facility, whereas there is often significant disruption in installing and plumbing in a vertical well network to protect the same area

HRWs have proven to effectively “multi-task” remediation: (1) provide negative pressure to eliminate vapor intrusion to the structure, and (2) effectively reduce VOCs in the subsurface, thereby remediating the plume.