Horizontal Directional Drilling (HDD) was recently used to optimize water well production for Milford Water Company’s site in Massachusetts. The Clark’s Island Wellfield consisted of 75 vertical 2.5-inch diameter water wells. This wellfield encountered several challenges, with water wells experiencing mineral buildup on the well screens, decreasing production to 50% of its original capacity. In addition, production was stopped during the winter months. The vertical wellheads were installed aboveground that made them susceptible to freezing. A reliable source of water was needed to restore production capacity.

Horizontal Water Well Layout

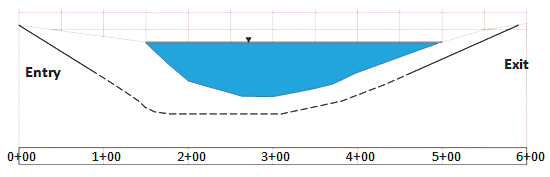

The geology of the Clark’s Island sand and gravel aquifer was a good candidate for HDD installation of horizontal water wells. A horizontal bore was directionally drilled 590 linear feet, and a 6-inch diameter horizontal water well was installed with a natural pack. The horizontal screen length spans 380 linear feet at a vertical depth of approximately 22 feet below ground surface.

- 6” IPS HDPE Well Materials

- 85’ Entry Riser, 125’ Tail Riser

- 380’ Well Screen, 40-slot

- Horizontal Depth 21-23’ bgs

- HDPE Heat-fused On Site

After developing the first horizontal water well, a 48-hour pump test was conducted. The horizontal water well produced 330 gallons per minute with a total drawdown of only 0.76 feet. Based on these results, a second horizontal water well was installed with a yield of 300 gallons per minute for a combined production capacity of 630 gallons per minute. The new horizontal water wells were installed with underground insulated wellheads to allow for year-round water production. For daily operation, the horizontal water wells are set to produce a combined 550 gallons per minute.

Milford Water Company shut down the existing 75 vertical wells and can achieve their maximum permitted production with the two (2) new horizontal water wells.

Horizontal Water Well Profile