Did you know that approximately 50 percent of horizontal remediation well projects have had some type of remediation previously performed through vertical wells?

Meaning, Directional Technologies is often designing and installing horizontal wells to achieve the remedial goals other technologies failed to reach. This article discusses just a few of the hundreds of projects where horizontal remediation wells were installed to expedite site closure and ultimately save millions of dollars for end users. Based on the successes of projects such as these, environmental consultants all over the country look to include horizontal wells during the first phase of remediation planning to see how horizontal wells can bring their next site to closure.

Example Site 1: Horizontal Bio-sparge Wells Remediate Residual Jet Fuel at Air Force Base

Source removal and free product recovery skimmers in vertical wells were unable to fully remediate the jet fuel impacted areas at a former Air Force Base. The most effective technique for remediation of the residual petroleum chemicals in groundwater proved to be with a horizontal well bio-sparging system. Through proper design, installation, and operation, five horizontal bio-sparge wells stimulated biodegradation of the remaining jet fuel chemicals below the state groundwater standards.

Read the Case Study: https://www.directionaltech.com/expediting-dod-site-remediation/

Example Site 2: Horizontal Groundwater Extraction Well Protects Off-site Properties for Landfill Leachate Migration

A capped landfill which was unregulated for several decades contributed to off-site migration of contaminated groundwater containing chlorinated solvent compounds and other dangerous chemicals. Vertical groundwater extraction wells were unable to provide a leachate migration barrier due to gaps in the radius of influence of the vertical wells. The downgradient residential properties were in danger of being impacted by the leachate migration. The solution: one horizontal well was designed to replace eight vertical extraction wells and eliminate the concerns of gaps in the influence of the vertical wells. Directional Technologies installed an 800 ft long horizontal groundwater extraction well at 45 feet below ground surface to regain hydraulic control of the off-site groundwater migration. After a successful installation, the horizontal groundwater extraction well recovered over 30 gallons per minute and created a hydraulic capture zone 700 feet long and 200 feet wide, which effectively cuts off contaminated groundwater migration off-site.

Read the Case Study: https://www.directionaltech.com/horizontal-extraction-wells-chlorinated-compounds-landfills/

Example Site 3: Horizontal Air Sparge / Soil Vapor Extraction Wells Expand Remediation System to Treat Off-site Impact

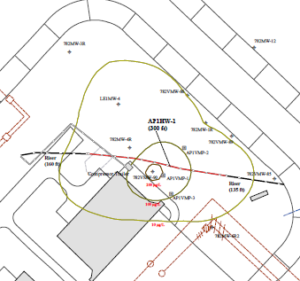

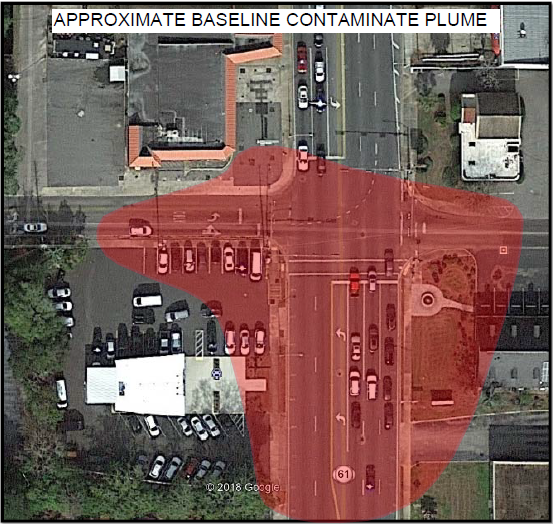

An active gasoline station located at a busy intersection was undergoing remediation with a dual phase extraction system with vertical extraction wells for many years. The radius of influence of the vertical extraction wells was not capable of extending the remediation system’s effectiveness to the off-site contamination beneath the intersection and down-gradient properties. The responsible party was facing potential liability for off-site contamination and possible vapor intrusion into buildings. To access the contamination under the intersection, eight horizontal wells (4 air sparge horizontal wells, and 4 soil vapor extraction horizontal wells), were designed and installed to extend several hundred feet beneath the intersection to remediate the off-site contamination.

Read the Case Study: https://www.directionaltech.com/how-to-remediate-under-an-intersection-with-horizontal-wells/

Example Site 4: Horizontal Bio-amendment Injection Expedites Perchlorate Site Closure

At an industrial complex, a leaking wastewater line impacted the on-site and off-site groundwater conditions with perchlorate. Downgradient contamination migration was also threatening a nearby river. Pilot testing vertical injection of bio-amendment resulted in some reduction of perchlorate concentrations; however, the vertical injection wells were slow to deliver the amendment due to lack of screen contact in the target sandy horizon. A better delivery system was needed to provide faster delivery of the amendment into the target zone. Directional Technologies installed two horizontal injection wells which resulted in 150 percent more submerged screen length compared to the vertical injection wells. The horizontal injection wells distributed the bio-amendment across the width of plume without gaps, helping to protect the river and achieve site closure in less than three years.

Read the Case Study: https://www.directionaltech.com/horizontal-bio-injection-leads-to-perchlorate-site-closure/