Clients are often left unsatisfied with traditional soil vapor extraction installations because the radius of influence doesn’t propagate beneath their building. Installing soil vapor extraction wells through horizontal directional drilling eliminates the client’s frustrations of business interruptions, while directly impacting the source to knock-out remaining soil contamination.

Horizontal Soil Vapor Extraction Wells

Horizontal soil vapor extraction (SVE) wells are the solution to preventing vapor intrusion at high-priority sites. Too many times contaminated sites remain active years beyond their lifespan simply because there is residual contamination located beneath a surface-level obstruction. Vertical wells installed along building perimeters can slowly chip away at spreading soil contamination, but the reality is that these systems cost money to operate, and clients don’t like spending money. The goal, then, is to knock out the contamination quickly and efficiently.

Advantages in Money and Performance

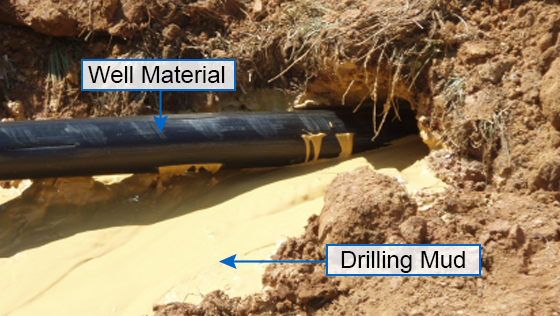

Horizontal remediation wells offer several advantages for soil vapor extraction, making them an effective solution monetarily and performance-wise. Through horizontal directional drilling techniques, horizontal soil vapor extraction wells can provide access to hard-to-reach places. Soil contamination can exist beneath roads, buildings, railroads, storage tanks, and more, all of which are areas that are inaccessible with vertical wells. This is particularly important in situations where vapor intrusion is a threat to business operations. Horizontal SVE wells can be installed directly below the building footprint, running parallel beneath the building foundation to provide enhanced coverage against harmful vapors.

Horizontal for More than Just Access

Soil vapor contamination does not just exist in access-restricted locations. Anywhere there is groundwater contamination, there is a potential for vapors to volatilize and migrate upward into the vadose zone. Horizontal wells can be installed with hundreds of feet or more of linear feet per well, providing improved efficiency as there is more surface area of the well in contact with the contamination. As a result, significantly more contaminant vapor can be captured and rerouted to the remediation system for treatment.

Horizontal wells reduce surface disruptions and restorations compared to vertical wells because multiple wells can be drilled and installed from one drilling pit. Several SVE wells can be installed in a fan-like layout to provide maximum lateral coverage while consolidating the wellheads to one central location. This is particularly useful at sites that are constrained in an urban or sensitive environment where vertical drill rigs do not have the space to operate.

Written by: Elliott Andelman, Professional Geologist