The Battelle Chlorinated Conference allowed hundreds of consultants to learn how horizontal remediation wells are used to overcome some of the greatest challenges facing environmental remediation professionals. For the thousands of consultants who couldn’t be there, we are sharing some insights presented as part of the event.

Below is a poster presentation from the conference that summarizes two case studies where horizontal wells were used as part of business-friendly remediation solutions.

- Access contamination underneath existing infrastructure

- Avoid interruptions to business activities and damage to existing buildings

- Successfully expedite soil and groundwater remediation using the advantages of horizontal remediation techniques and Directional Technologies’ custom-engineered well designs

Case Study 1: Former Industrial Site Turned Residential

A former industrial site had been redeveloped with several buildings containing a large number of multi-tenant apartment units and commercial tenants. PCE and TCE concentrations within the soil vapor exceeded the residential area’s screening levels, threatening the tenants’ indoor air quality. Assessment of the contaminant plume revealed that the former source areas were located directly beneath various occupied first-floor apartment units. The building owner asked the environmental consultant if they could find a way to solve the vapor intrusion issues without requiring tenants to vacate their units and also avoid damaging the structure of the building.

To solve their client’s problem, the consultant reached out to Directional technologies to install 11 horizontal vapor extraction wells into precisely targeted locations. The horizontal wells ranged in lengths from 140 feet to 370 feet long and targeted soil vapors at approximately 6 feet to 10 feet below the land surface (bls).

The horizontal vapor mitigation system was installed with no impact on the occupants and no damage to the building. When the horizontal wells were connected to the vapor extraction blower, better than expected vacuum influence provided enough subsurface air movement to reduce soil vapor concentrations to safe levels for the residents.

Case Study 2: Manufacturing Facility

A Midwest manufacturing facility operated for over 70 years, machining various stainless-steel products. Before environmental regulations, the facility used in-ground degreaser pits as part of its operations, which resulted in significant TCE-impacted soil and groundwater across a wide area. In subsequent environmental investigations, vapor intrusion posed indoor air quality issues for workers. The facility interior was not only crowded with large machining equipment but also operated two shifts around the clock. The facility owners were sensitive to the disruption of their operations, estimating that the lost revenue from shutting down their typical business activity for even a few days would cost them vastly more than the price of installing the remediation system. These factors significantly complicate installing a vapor mitigation system to address the vapor intrusion concerns.

To help them find a solution that would satisfy the facility owners while also not compromising on the effectiveness of their planned SVE system, they reached out to Directional Technologies for assistance. A plan was ultimately approved to install 7 horizontal sub-slab vapor extraction wells. The wells were installed from outside of the building and connected to vapor extraction system. Drilling was conducted via blind (single-entry) bores staged on the side of the building that would not impact facility operations. The horizontal SVE wells were installed at depths of 5 feet to 9 bls.

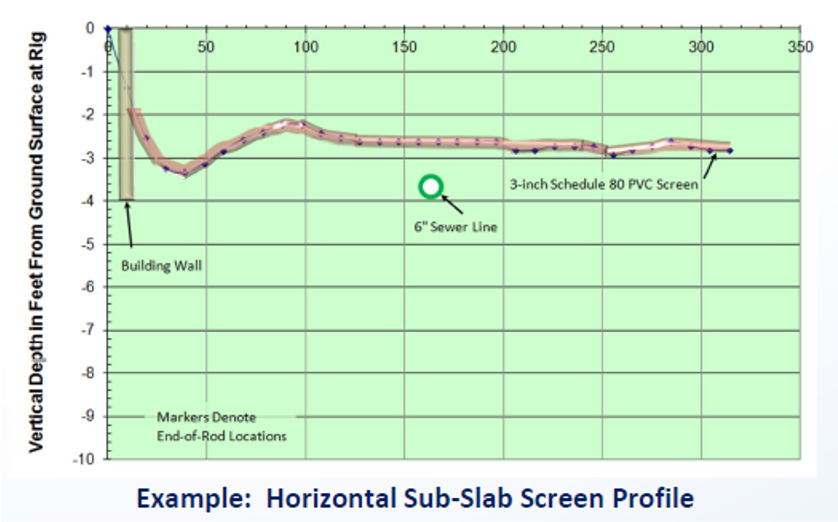

Plan-view layout of a typical horizontal SVE Well

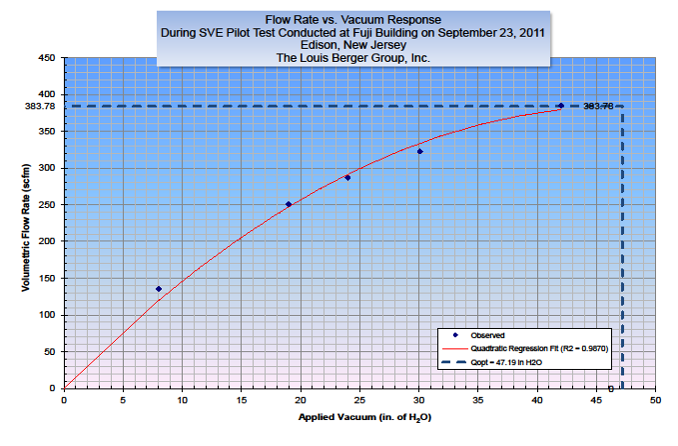

Chart of flow rate versus vacuum of a typical horizontal SVE Well

Click Here For High-Resolution Poster Image

What business interruptions could you help your clients avoid by using horizontal remediation wells? Contact our horizontal well experts at 1-877-788-4479 or drilling@directionaltech.com to discuss your current project needs.