We’ve all heard the saying that good fences make good neighbors. When it comes to managing the migration of contaminant plumes to adjacent properties, choosing the best way to fence in subsurface contamination can often make the difference between a moderate-sized cleanup in the near future and a large-sized cleanup further down the road. Here’s how one of our clients teamed up with Directional Technologies to implement their remedial strategy incorporating a solution to off-site concerns at an airfield located in the southern United States.

Challenge

The airfield contained several areas of subsurface jet fuel contamination. Following the installation of a free product recovery system consisting of vertical recovery wells, dissolved concentrations of VOCs above regulatory cleanup criteria were still present in some areas. The client was tasked with bringing the site to closure without disrupting the day to day operations and preventing the spreading contaminant plume from impacting adjacent properties.

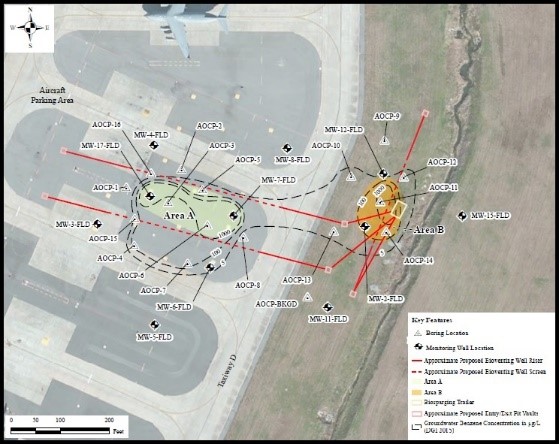

The site contained two source areas with a comingled contaminant plume located near the property boundary. The western portion of the plume was underneath an aircraft parking area, and the eastern portion of the plume was in an open, unpaved area. The majority of the groundwater contamination in these areas occurred within a clay unit. Data from vertical monitor wells indicated that the contaminant plume was migrating towards a nearby stream located along the eastern property boundary.

Solution

The first draft of the proposed remediation plans consisted of two parallel biosparging horizontal remediation wells running underneath the aircraft parking area. The horizontal screen intervals were designed to target the western portion of the contaminant plume as well as a separate array of vertical wells placed near the property boundary to remediate the eastern edge of the plume and contain off-site migration. The plume in this vicinity was approximately 300 feet wide. Directional Technologies used its experience of installing over 1,000 horizontal wells and, as a value-added option, proposed an alternative remediation design. An engineered third biosparging horizontal remediation well was suggested to replace the array of multiple vertical wells that were proposed along the property boundary. Adding a horizontal well might initially seem counterintuitive to controlling project costs. However, the addition of the horizontal well not only allowed for a reduction in overall costs by replacing the need for multiple vertical wells but also provided for a more effective remedial solution by dramatically increasing the well screen surface in contact with the contaminated media.

The three horizontal remediation wells totaling almost 1,000 feet of combined length were constructed of 3-inch diameter HDPE with custom-designed well screens tailored to site-specific conditions. The horizontal well screens were designed for air delivery rates of 0.1-0.25 cubic feet per minute (cfm) per foot of screen. The horizontal wells were installed to a depth of 17 feet below the ground surface. After the horizontal wells were operational and connected to the remediation system, performance data collected from nearby vertical monitor wells confirmed the effectiveness of the horizontal remediation wells. The plume had been effectively remediated without spreading further, and the site achieved closure. The consultant’s client was ecstatic that no further action was needed, and business continued during the remedial construction.

Did you know that one horizontal well can potentially take the place of five or more vertical wells?

For plumes with a wide lateral geometry, the number of vertical wells required to keep a plume from migrating off-site can become a frustratingly costly proposition. Call our horizontal remediation well experts at 1-877-788-4479 to discuss your current project needs.

With groundwater flow to the east, the plume (black line) was migrating towards a surface water stream that ran parallel to the property boundary. A third biosparge well (red line) oriented along the property boundary was installed to remediate the portion of the plume originating from Area B as well as to prevent the migration of contamination to adjacent properties.