When to Step Up to Stainless on a Horizontal Well? Need for longevity.

At challenging sites where decades of remediation will be required rather than years, consultants have wisely selected Directional Technologies to install stainless steel horizontal remediation wells (HRWs) due to the longevity the stainless steel horizontal well material provides.

Challenging target depths.

Horizontal stainless steel well materials are stronger than PVC or HDPE, and therefore can withstand greater installation pressures associated with deep target depths.

High-temperature tolerance.

Horizontal stainless steel wells can provide conduits for thermal remediation applications such as steam injection. High pressure steam injected into wells can reach temperatures about 500 degrees F. PVC or HDPE well materials will not be able to withstand these temperatures.

Challenging subsurface conditions.

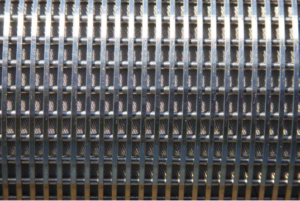

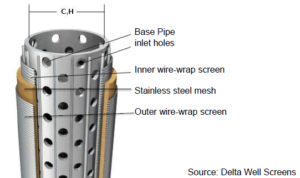

Stainless steel horizontal wells can be constructed with an inner or outer wire mesh jacket designed for a specific micron porosity to prevent fine particles from entering the wells screen. Horizontal stainless steel wells can be installed within subsurface lithologies of coarse grained materials like sands and gravels or fine grained materials such as clays or coal ash.

Difficult areas to access.

Horizontal stainless steel wells can be installed in areas where vertical drill rigs cannot access. Beneath landfills, manufacturing facilities, roadways, railways, wetlands, pipelines, etc.

The Power of Stainless Steel. Stainless steel horizontal wells continue to be a powerful tool for solving long-term remedial challenges. Environmental consultants with concerns and frustrations of deep contamination, offsite plume/leachate migration, challenging subsurface conditions, and contamination beneath inaccessible areas have all benefited from solutions provided by the use of stainless steel horizontal remediation wells.

Real world success: Groundwater extraction with stainless steel HRWs

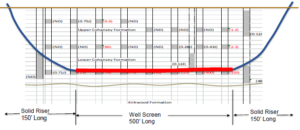

Landfill leachate containment is one example of where stainless steel horizontal wells have solved leachate control issues. These sites need remediation for decades if not “life-long” remedial solutions. Horizontal stainless steel groundwater extraction wells installed along the perimeter of the landfill can provide permanent protection for offsite properties. High flow submersible pumps are installed into the wells to extract groundwater and provide hydraulic control of the offsite migration of the leachate. The following information details a site where DTI installed a stainless steel horizontal groundwater extraction well installed at a superfund landfill site. Read the full landfill leachate control case study.

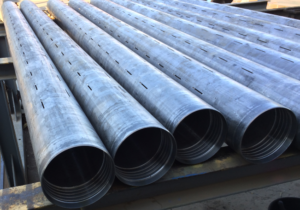

Stainless steel horizontal well construction

Stainless steel horizontal wells can be constructed of 2-inch to 8-inch nominal diameter pipe. Precise screen slotting for the desired fluid extraction/injection rates are designed for site specific site conditions. In addition to slotting, many stainless steel horizontal wells are constructed with a wire mesh wrapped jacketing, either on the exterior or within the interior of the stainless steel casing. The stainless steel jacketing can be designed for specific micron mesh to prevent fine particles from entering the well. Therefore grain-size analysis of the target zone is important data to collect when planning for the project.

Cost-effectiveness

Horizontal stainless steel wells are cost effective when compared to multiple vertical stainless steel wells. In addition, operation and maintenance of multiple vertical wells can cost more than the O&M costs of one horizontal well. DTI may recommend that only the screen section of the horizontal well be constructed with stainless steel. For groundwater extraction applications, the entry and exit riser portions of the well can be constructed of HDPE to reduce overall costs.Horizontal stainless steel wells are a proven, cost effective means to provide reliable long-term remediation to challenging sites.