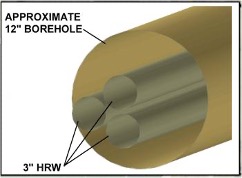

Environmental consultants have relied on horizontal remediation wells (HRWs) to deal with some of their most challenging remediation projects. With many experienced consultants seeking to expand their remediation toolkit and new consultants entering the field looking to learn about specialized remediation techniques, it is beneficial to be aware of what types of remediation can be using horizontal wells. Many consultants are surprised to find that anything that can be done via traditional vertical wells can also be done via horizontal wells, oftentimes with a shorter timeline to achieve remediation goals, little to no business disruption, and a host of other benefits.

Also, horizontal wells add an additional degree of versatility that you won’t often see with traditional vertical wells. Thanks to Directional Technologies’ unique approach to site-specific well screen design, horizontal remediation wells can be engineered to allow for multiple in situ remediation techniques to be applied to a horizontal well installation. In various cases, a remediation project may begin with one in situ strategy applied to horizontal wells and later transition to a completely different approach.

Below we describe just a few of the ways that horizontal remediation wells have been used to remediate even the most challenging sites. Each category includes a brief overview of a representative project that was performed by Directional Technologies’ horizontal remediation experts.

Injections (ISCO, ISCR, Bioremediation)

Taking advantage of custom-designed horizontal wells with segmented screen sections, isolated remedial injections were targeted to deliver treatment in precise locations and concentrations. Ten horizontal injection wells were installed beneath an occupied building to address chlorinated solvent contamination in the groundwater. Each horizontal well was designed with three discreet screen segments to precisely target different treatment zones. The in-situ chemical oxidation plan involved the injection of a sodium permanganate amendment into the sandy clay layer.

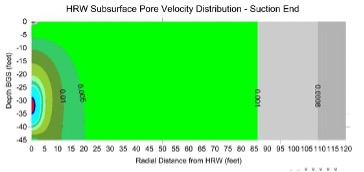

Sparging (Air sparge, Biosparge)

A 50,000-gallon release at a bulk fuel storage terminal had been under remediation for over a decade using traditional techniques. The consultant had successfully remediated large portions of the plume, but contamination of several acres in size still persisted in the vicinity of sensitive receptors. Engineering analysis revealed that a total of 129 vertical wells coupled with 23 blowers would be required to remediate the entire affected area via bio-sparge technology. The analysis further revealed that only 12 horizontal biosparge wells coupled with six blowers would be required to remediate the same area. These biosparge wells successfully achieved mass removal goals as well as controlled contaminant migration.

Vapor Extraction (SVE, SSDS, Passive Venting, Dual Phase, Bioventing)

A redevelopment plan for a former industrial site had been placed into a fast-track mode, and the consultants were required to begin remedial action on a short timeline. However, due to the redevelopment plans, their initial vertical well design would need to be abandoned shortly after the first year of operation to allow for the redevelopment construction to take place and would have to be reinstalled to continue the remediation efforts once redevelopment construction was completed. A horizontal well solution allowed the consultants to identify a solution that would enable them to continue remediation efforts during the redevelopment without requiring abandonment and reinstallation of the remediation wells. Seven horizontal SVE wells were installed to treat contamination in the vadose zone. Mass removal rates of 405 pounds per day for VOCs and 62 pounds per day of methane were measured after the first year of operation, and a radius of influence of up to 85 feet was achieved.

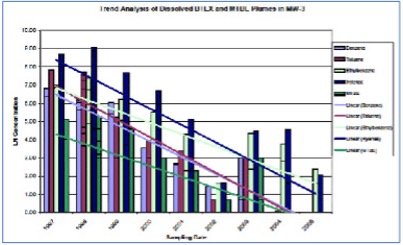

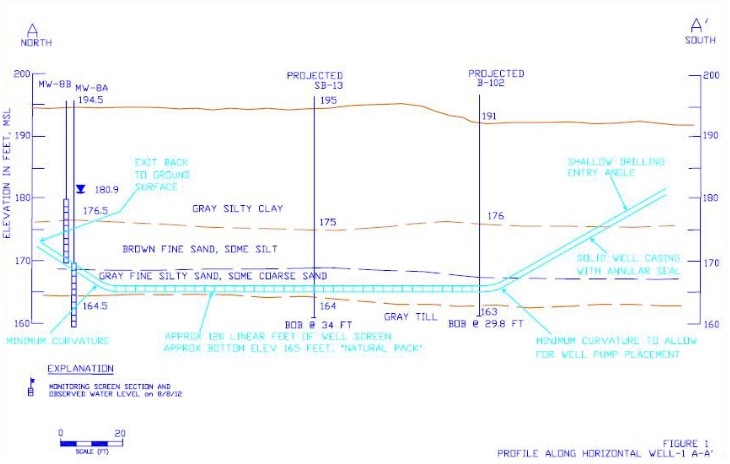

Groundwater Extraction (Pump and Treat, Hydraulic Control, Dewatering, Dual Phase)

Various VOCs at a landfill site required treatment; however, disturbing the landfill cap was a major concern. Groundwater impacts were along a thin layer of gray fine silty sand directly above bedrock. Horizontal wells would allow a remediation system to be installed in the target zone without disturbing the landfill itself and also provide a greater capacity to recover groundwater in the narrow target zone. Two horizontal extraction wells were installed using precise tracking techniques to ensure that the wells would produce the highest yield.

Would an evaluation of horizontal wells at your next project site help you run a more successful project? Contact our horizontal well experts at 877-788-4479 or drilling@directionaltech.com to discuss your current project needs.