Abstract

Environmental injection wells are used to deliver a variety of fluids into porous media for the purpose of in situ soil and groundwater remediation. Injection wells are used to deliver nutrients for enhanced bioremediation; various amendments for bioaugmentation; and potassium or sodium permanganate, or mixtures of ozone and peroxide for chemical oxidation. Remediation agents are injected in both liquid and gas states, and they have a wide range of physical properties, such as temperature, density and viscosity. Long screens are often specified in order to deliver efficiently into large soil or aquifer volumes. The screens may be vertical, horizontal, or inclined, depending on hydrogeology and plume geometry. Some screens have variable inclinations, such as horizontal screens that continue into the riser section. Complete and efficient sweep of the targeted volume of porous material is ensured if long screens are engineered to provide

uniform injection of the fluid.

Mechanical requirements for achieving uniform fluid injection center around three design elements: pipe flow, orifice flow, and porous media flow, which are used to define the three stages of the injection process: generation of positive pressure by the treatment system at the ground surface; establishment of a pressure gradient through the conveyance pipe and well screen; flow through the pipe; flow through the screen slots; and flow into the formation. The flow process depends on physical specifications of the pipe and screen, and on formation properties. Pipe and screen specifications include pipe material and roughness factor; inner and outer pipe diameter; pipe inlet and outlet elevations; length of conveyance pipe, well riser, and screen; screen slot dimensions and orifice coefficient; and open area distribution along the screen. Formation characteristics include pneumatic or hydraulic conductivity of the formation; and hydraulic head elevation and

gradients. Sensitivity analyses provide an understanding of the relative influence of these parameters, and guidance in focusing the design effort.

Design of an injection system accommodates boundary conditions set by the treatment system capacity, well material properties, drilling conditions, and anticipated response of the aquifer or soil zone to the injection process. Monitoring of wellbore and aquifer conditions during well drilling and development provides data about subsurface conditions that can be used to adjust and optimize the operation parameters for the injection system. A series of examples illustrates typical and end-member cases of injection of liquids and gases with different fluid properties, into wells made of commonly used pipe materials, and into various geologic media.

Introduction

Efficient delivery or extraction wells are the lifeblood of effective in situ remediation systems. A successful screen design achieves the necessary balance of screen dimensions and operational parameters, and is appropriately tuned to material properties of the various media involved, to achieve uniform delivery or extraction of sufficient volumes of fluid or gas to effectively remediate the target zone. Fluids and gases used in such systems include:

- • Air

• Water

• Bioamendment solutions

• Chemical oxidant solutions

• Soil gas

• Groundwater and non-aqueous fluids

This paper examines the effect of key design parameters on the efficiency of well screens. Although a well screen of any length should be engineered to be effective, the design parameters discussed in this paper are especially relevant to long screens. The need for proper screen design applies equally to vertical wells, horizontal wells, and inclined wells.

Design Parameters

The size of the zone of influence of a fluid injection or soil vapor well is directly proportional to the flow rate. For a fluid injection well, the zone of influence is proportional to the rate of delivery of fluid into the soil formation. For a soil vapor extraction well, the zone of influence is proportional to the extraction rate of air out of the formation.

As the flow rate increases, so does the hydraulic head gradient from an injection well into the formation, or the negative pressure gradient between a soil vapor extraction well and the formation. The efficiency of the fluid delivery or vapor extraction system

depends on the balance of pressures and flow rates applied at the surface, and resistance to flow along the entire flow path, which is influenced by a series of material characteristics encountered by the fluid or vapor, including:

- • Roughness coefficient of the pipe

• Slot apertures

• Hydraulic radius of slots or orifices

• Depths of screen slots (pipe wall thickness)

• Distribution of slots along the screen (percent open area of screen)

• Hydraulic or pneumatic conductivity of the formation

• Skin factor of the well

The skin factor of the well is a measure of formation damage that develops adjacent to the well screen, which reduces the well’s effectiveness in delivering or extracting fluid or gas. By contrast, operation of a well can cause beneficial changes in formation adjacent

to the well screen. This process is causes the formation of a natural filter pack. This self-development of a well depends on several key formation parameters:

- • Sphericity of the grains comprising the formation

• Average diameter of the grains

• Grain size distribution, or grain sorting

During the operation of a fluid injection well or a soil vapor extraction well, the pressure gradient within the formation depends on a series of physical parameters, many of which are interrelated. These parameters include the material characteristics listed above, and:

- • Viscosity of the injected fluid or extracted gas

• Pressure gradient along the well screen

• Flow rate of air through the well screen

• Reynolds number

• Diameter of the well

• Length of the well screen

• Length of the riser pipe

• Length and diameter of conveyance piping

• Depth of the well

The delivery of fluid into the formation or extraction of vapor out of the formation sets up a pressure gradient from the well to the edge of the well’s zone of influence. This pressure gradient drives fluid or vapor transfer between the well and the formation. The steeper the pressure gradient, the faster groundwater or soil vapor will be replaced within the pore spaces of the treatment zone. Pore fluid around an injection well becomes enriched with the constituents of the injected fluid. Soil gas around a soil vapor extraction well is removed from the formation by flowing into the extraction well. Various degrees of mixing occur in both the fluid injection and soil vapor extraction processes. Treatment of the target zone is expedited when the fluid or vapor phase is driven to move quickly through the well’s zone of influence. Pressure gradients around the well directly impact the rate of treatment of the target zone.

PRESSURE GRADIENT AND INJECTION RATE

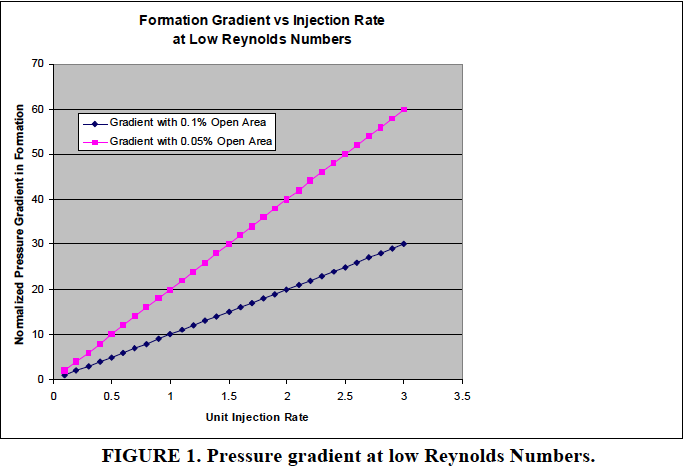

Four plots of the pressure gradient as a function of the unit injection rate along the well screen illustrate the effect of injection rate on the pressure gradient that drives the rate of treatment of a target zone. Two plots are shown in Figure 1, representing different

open area values.

The pressure gradient is normalized with respect to the gradient. The plots show a direct proportional increase of pressure gradient with increasing injection rate. A three-fold increase in injection rate produces a three-fold increase in pressure gradient. The effect of screen open area is to increase the rate at which pressure increases with increasing flow rate.

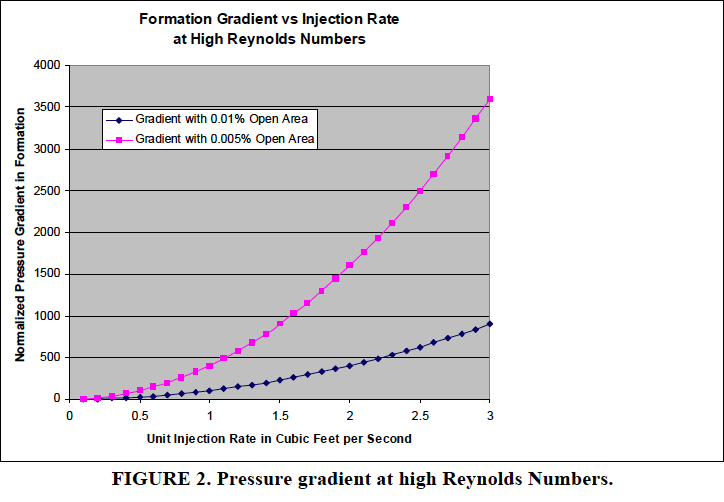

Figure 1 represents flow at low Reynolds Number values. Flow under these conditions is considered to be laminar. Liquid injection can be designed to maintain laminar flow through the well screen, preventing encrustation of the well. By contrast, soil vapor extraction wells commonly develop turbulent flow conditions. The two plots in Figure 2 represent the increase in pressure gradient in response to increasing flow rates under flow conditions with relatively high Reynolds Number values. The plots show a non-linear increase of the normalized pressure gradient with increasing flow rate. Under these flow conditions, the pressure gradient increases by several orders of magnitude while the flow rate increases by integer amounts. The two plots in Figure 2 represent screen open areas that differ by a factor of two, and illustrate the increased sensitivity of flow rate to the pressure gradient with decreasing open area of the well screen.

SCREEN OPEN AREA AND FLOW DISTRIBUTION

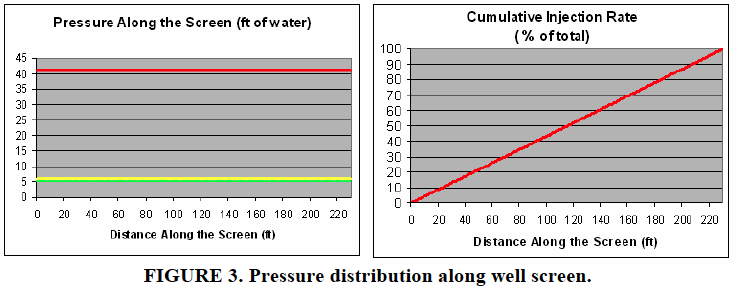

Besides showing the effect of injection rate on the pressure gradient that drives the rate of treatment, the plots above also illustrate the sensitivity of fluid injection well effectiveness to the open area along the well screen. The following example illustrates how the efficiency of a liquid injection well is influenced by small changes in the percent open area along the well screen. Figure 3 shows the pressure distribution and cumulative flow rate along a properly designed, 230-foot long well screen. The left hand side of Figure 3

shows an even pressure distribution along the screen, while the right hand side shows that the cumulative injection rate reaches 100 percent at the end of the well screen.

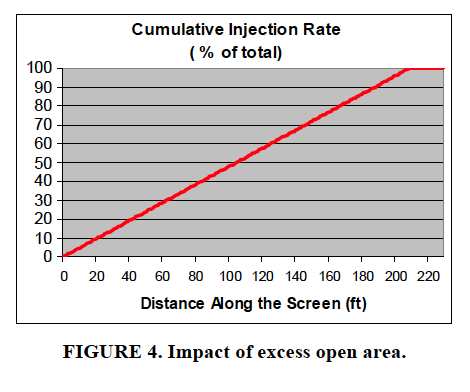

Small changes in open area can be detrimental to the effectiveness of the well. Figure 4 shows the impact along the well screen of a ten percent increase in open area over the optimal amount. The cumulative injection rate reaches 100 percent about 20 feet before the end of the well screen. This means that 20 percent of the screen is ineffective.

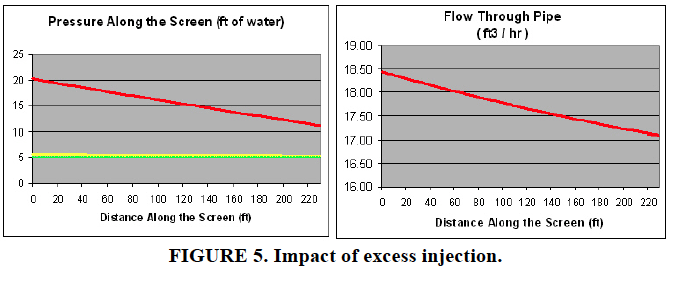

Pressure drop along a well screen may become excessive, as shown in Figure 5, if the well specifications, such as well diameter, length, depth, and screen design do not match the operational requirements, such as injection rate and injection pressure, and do not

take into consideration material properties of the well pipe and target formation. The red plot on the left hand side of Figure 5 represents pressure drop, measured in feet of water.

The lower plot represents background pressure in the formation. Excessive pressure drop can lead to a declining injection rate along the well screen, as shown on the right hand side of Figure 6. The same engineering principles apply to the design of extraction well

screens. For example, an imbalance of vacuum and flow rate against the well specifications and formation characteristics can lead to a large pressure drop and unacceptably declining extraction rates along a soil vapor extraction well screen. Problems with high

pressure drop are more common under typical operating conditions for soil vapor extraction wells than they are for fluid injection wells.

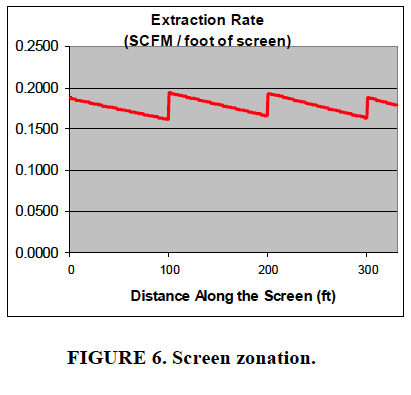

ZONED SCREENS

Problems associated with high pressure drop in an injection or extraction well can be resolved by adjusting the well diameter or by progressively changing the open area along the well screen. Typically, the open area is increased in 100-foot intervals toward the distal

end of a well screen, which is the point furthest away from the source or blower. This is referred to as zoning the screen. Open area zones are designed so that the average injection or extraction rate is constant among the zones, as illustrated in Figure 6 for a soil vapor extraction well.

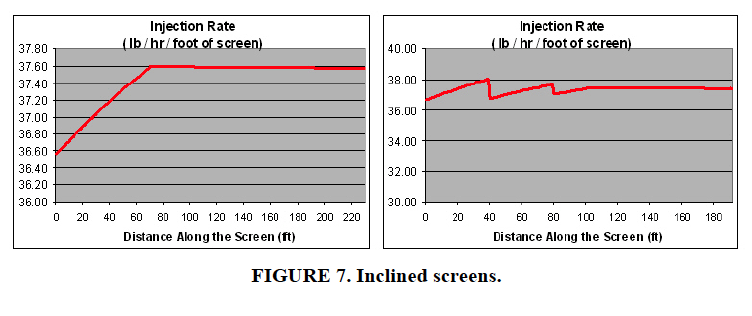

INCLINED SCREENS

Changes in screen elevation also affect flow distribution along a horizontal well. The example in Figure 7 shows changes in fluid injection rate along the screen of a liquid injection well with slots extending partially into the curved riser section of the well. The screen represented on the left hand side of Figure 7 has a constant open area along the entire screen, including the shallower portion of the screen on the left. The screen represented on the right hand side of Figure 7 is zoned to adjust to the changing screen elevation. As in the previous example of a soil vapor extraction well, the liquid injection well can be designed to achieve even distribution of flow along the well by dividing the

screen into several zones with progressively changing open areas. The liquid injection screen in the example below is divided into three sections, or open area zones.

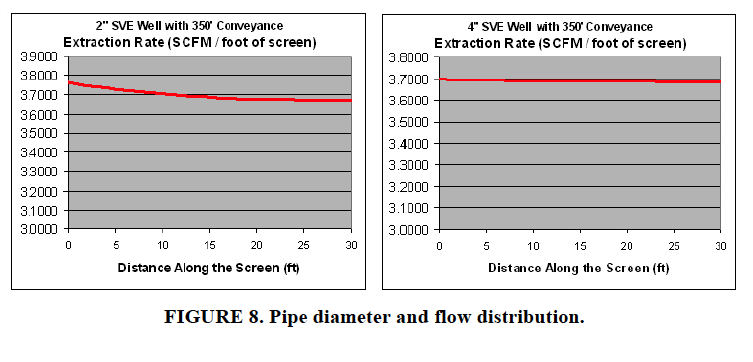

PIPE DIAMETER

The sensitivity of pressure and air flow distribution is enhanced at high vacuum, high air flow rate, and small well diameter. The latter is illustrated by the comparison of extraction rates along two wells with different diameters, in Figure 8. The distribution of the extraction rate along a 2-inch diameter screen is shown on the left hand side, and the extraction rate along a 4-inch diameter screen is shown on the right hand side of Figure 8. The flow rate is essentially constant in the 4-inch well, but decreases away from the blower in the 2-inch well.

CONVEYANCE PIPING

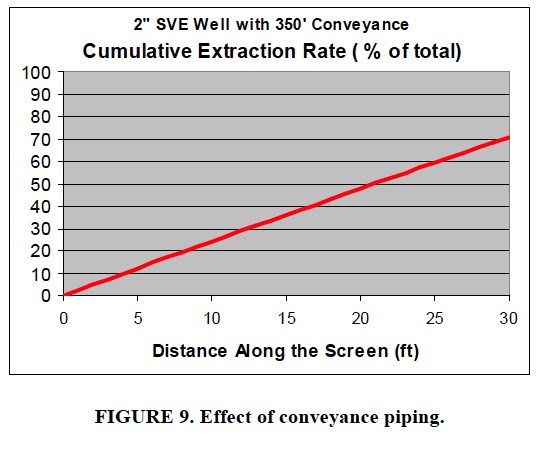

Finally, the importance of taking into account the length or diameter of conveyance piping between the blower or fluid source and the wellhead is illustrated by the Figure 9, which shows the cumulative extraction rate for a soil vapor extraction well which was

designed without taking into account several hundred feet of conveyance piping. As a result, the well produces only 70 percent of the air flow required by the design. The low air flow rate will result in diminished performance of the remediation system. The design must also account for changes in pipe diameter or pipe materials. Compared to the effect of pipe diameter, the effect of pipe materials is small.

2″ SVE Well with 350′ Conveyance

CONCLUSION

Proper sizing and design of wells and well screens is essential to successful delivery or extraction of agents used for in situ soil and groundwater remediation. The open area of a wells screen determines its ability to distribute flow evenly along the entire length of the screen. Screen zonation is one mechanism for equalizing flow, but equal flow can also be achieved by adjusting well diameter or operational parameters, such as pressure or total flow rate. Problems of variable well elevation can also be addressed with screen

zonation. Proper engineering of well screens must also account for conveyance lines.

Most important among the design considerations is that the design assumes operational parameters that will cause sufficient volumes of fluid or gas to be delivered or extracted for the system to effectively remediate the target soil zone, water-bearing unit, or aquifer.

Paper E-037, in: Bruce M. Sass (Conference Chair), Remediation of Chlorinated and Recalcitrant Compounds—2008. Proceedings of the Sixth International Conference on Remediation of Chlorinated and Recalcitrant Compounds (Monterey,CA; May 2008). ISBN 1-57477-163-9, published by Battelle, Columbus, OH, www.battelle.org/chlorcon. Michael J. Sequino, Directional Technologies.