Physical site constraints, in combination with shallow groundwater, have led more consultants to target exposure pathway elimination with horizontal remediation wells. Gas stations are one of the most common facilities requiring a remedial response due to compromised underground storage tanks (USTs) and leaks resulting from fuel dispenser piping failures. Fuel contamination can go undetected for years, allowing sufficient time for the contamination plume to amass to concentrations above regulatory limits. Accumulation of contamination beneath a facility often leads to a threat of vapor intrusion through the facility’s sub-slab, creating dangerous working conditions if proper remediation does not take place. Recently, Directional Technologies (DTI) partnered with an environmental consultant to address the vapor intrusion and enclosed space inhalation exposure pathways using horizontal remediation wells (HRWs) because of an ongoing fuel leak at an active gas station in Nebraska.

Background and Setting

The gas station site was located in an alluvial flood plain characterized by relatively flat terrain. Boring logs confirmed that lithologic conditions beneath the site consisted primarily of lean clay with thin intermittent lenses of sand. The presence of free product non-aqueous phase liquids (NAPL) has been detected within existing monitoring wells at the site since 2007. Depth to groundwater at the site was shallow, ranging between 2.0 and 9.3 feet below ground surface (bgs), and the core of the soil contamination resided beneath the fuel dispenser canopy.

The Nebraska Department of Energy requested a remedial action plan to address the enclosed space inhalation soil pathway and free product removal at the site. Due to access constraints at the site involving the fuel dispensers and gas station facility, horizontal drilling was proposed to install screened laterals and conveyance piping for the soil vapor extraction (SVE) system in lieu of traditional trenching.

Enclosed Space Inhalation and Vapor Intrusion Pathways

The presence of free product in the soil beneath the facility enhanced the threat of a vapor intrusion pathway, providing inhalation hazards for employees and customers of the active gas station. Additionally, the shallow depth to groundwater introduced additional complications. In addition to the obvious site constraints of an operating gas station, shallow groundwater reduces the space in the vadose zone for traditional vertical wells to address soil contamination effectively. Without proper soil remediation, the constituents can leach into the shallow groundwater and then migrate off-site, introducing additional vapor intrusion threats to surrounding businesses. The plume’s location beneath the fuel dispensers and active gas station facility, along with the shallow water table, ultimately led the consultants to implement a horizontal remediation system rather than a traditional vertical system. By utilizing horizontal drilling and installation techniques, on-site disturbances of commercial activities and vehicular traffic on the gas station property could be minimized during all phases of the remediation process.

Designing a Successful Horizontal Remediation System

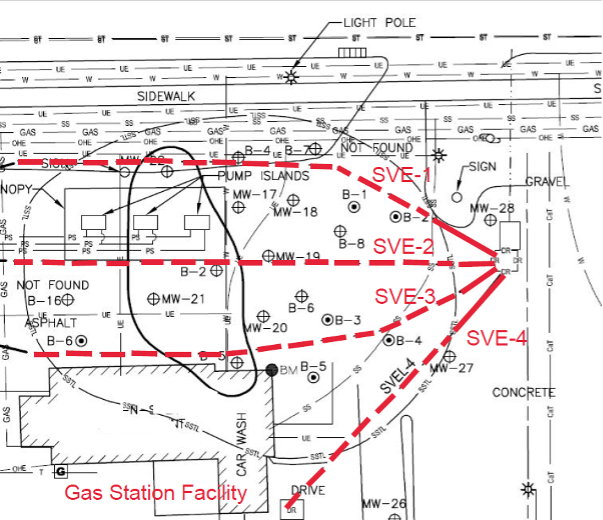

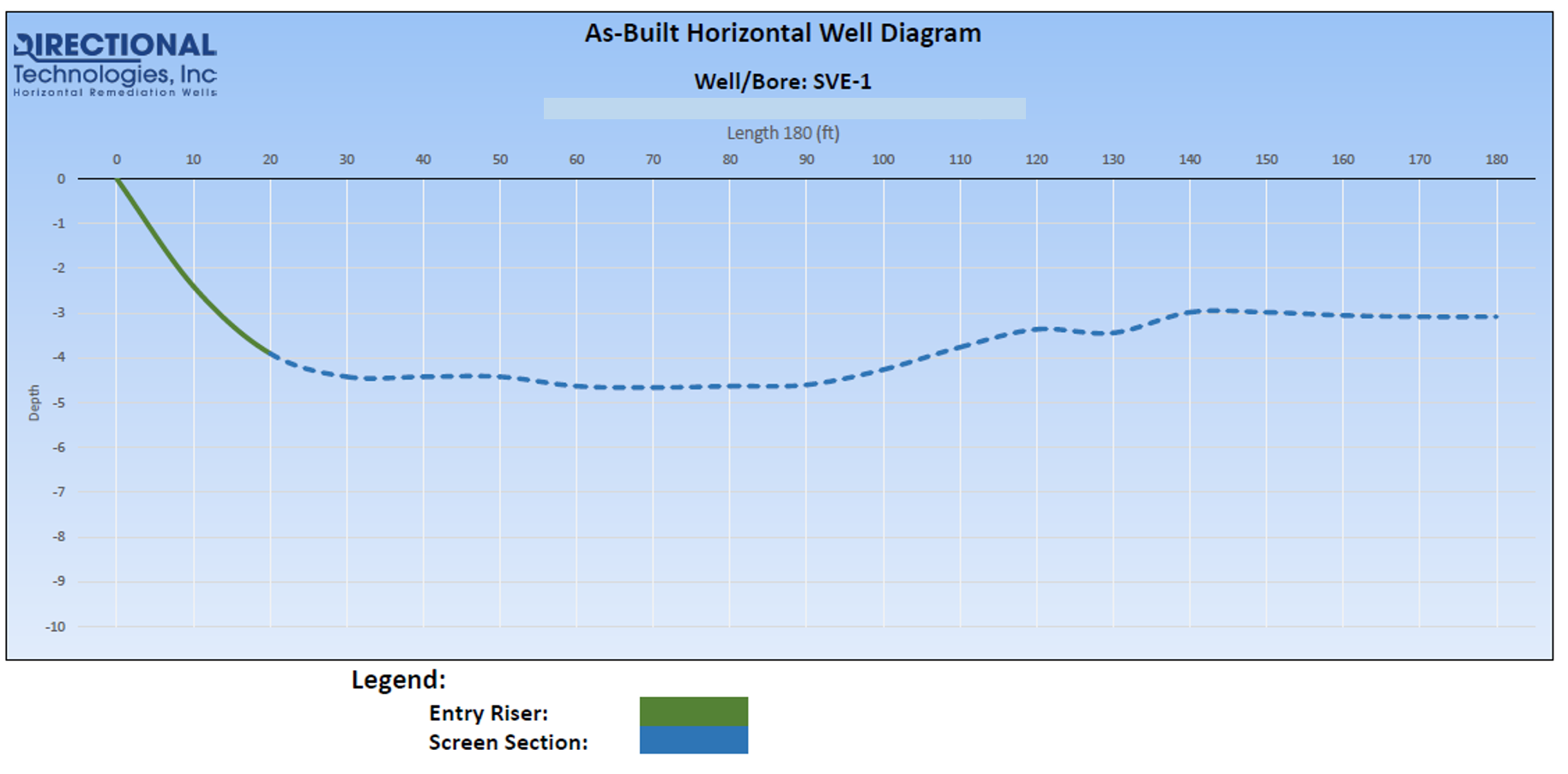

Directional Technologies teamed up with the consultant to help design and implement a horizontal remediation system that would meet the remedial goals of the project. The primary objective of the horizontal system was to overcome the obstacle of the existing on-site facility and fuel dispensers while providing optimal access to the source area soil contamination to mitigate vapor intrusion. DTI installed four horizontal SVE wells to address the contamination at the site. As shown in Figure 1, horizontal wells SVE-1 through SVE-3 were constructed of 3” PVC and extended to a length of 180’, with 160’ of screen. SVE-1 bounded the north end of the plume, while SVE-3 was installed to act as a barrier along the entrance of the gas station facility, preventing the threat of vapor intrusion into the store. SVE-2 was installed to address the core of the plume closest to the fuel dispenser canopy. The groundwater flow direction was generally to the southeast, threatening the off-site migration of the contaminant plume. To combat this, SVE-4 was installed in the vadose zone perpendicular to groundwater flow along the southeast edge of the property, totaling 130’ in length with 100’ of screen. The purpose of this design was to surround the soil contamination plume while simultaneously targeting the source area and providing a protective barrier to the building.

The wells were all installed via blind installation technology, meaning only an entry point was required, with the well terminating at the end of the screen below the ground surface. Blind installations are particularly useful at site locations where on-site obstructions prevent access to the contamination. (See this post for more information about blind installations.) All horizontal SVE wells were installed to a maximum depth of 5 feet below the ground surface to prevent interaction with the shallow water table while the remediation system was active.

Results:

Directional Technologies successfully installed the four horizontal SVE wells despite the physical challenges at the site. The four horizontal SVE wells served individual purposes to contribute to a cohesive remedial goal. SVE-1 bounds the property’s northern edge, while SVE-4 creates a downgradient contamination barrier. SVE-2 intercepts the plume’s core, while SVE-3 traverses the building front to prevent collection of contamination beneath the existing gas station facility. When activated, the system’s design successfully addressed the two main remedial concerns of eliminating the enclosed space inhalation threat and vapor intrusion caused by elevated soil contamination.

How can the advantages of decades of technological advancement in horizontal wells benefit your project? Call our horizontal remediation well experts at 1-877-788-4479 to discuss your current project needs, or click HERE to complete our online form.