Horizontal remediation wells used for injection of CLout® for anoxic bioremediation of perchlorate plume

Background

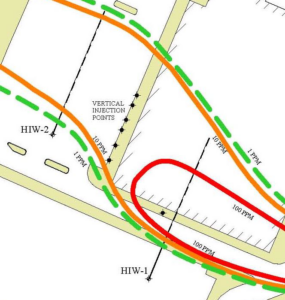

A plume of perchlorate in groundwater, which was a consequence of industrial process wastewater leaking from a drain line at a facility in Massachusetts, went undetected for approximately 8 to 10 years. Perchlorate concentrations in the plume were 10 to 500 mg/L and the estimated mass within the plume was on the order of 1,500 pounds of perchlorate. The plume extended over 900 feet down slope toward the nearby river, and the width was less than 120 feet. The plume traversed beneath an occupied industrial building, active parking lot, and roadway.

Site Geology and Hydrogeology

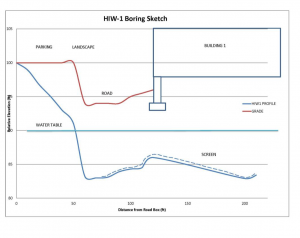

The overall groundwater flow beneath the site is toward the northwest, down slope toward the adjacent river. The formation permeability was calculated at 3.5 feet per day. The alluvium above the bedrock, which varies in thickness from 15 to 20 feet across the site, consists of 0 to 6 feet of granular fill overlying a sequence of glacially deposited sand and gravel and a thin layer of dense till. The calculated groundwater velocity was 120 feet per year. The groundwater flow rate was confirmed by tracking time to travel with additive injections.

Remediation Strategy

IRWIN Engineers demonstrated the viability of in-situ bioremediation of perchlorate using CLout® cultures. Bench scale treatment with CLout®, buffer, and a soluble carbon source reduced 100 mg/L perchlorate to less than 1 mg/L within 60 days, and pilot testing with a row of five vertical injection wells across a section of the plume closer to the source demonstrated successful in-situ performance. Based upon that success, the decision was made to convert existing vertical extraction wells into injection wells for bioaugmentation treatment.

Installation Process

Pilot borings were drilled to 6-inches in diameter, and reamed to 10-inches in diameter. The drill rig selected for the horizontal well installation was a Vermeer D80x100 Series II Navigator capable of 10,000 ft-lbs of torque and 80,000 lbs of thrust. Wire-line location system was used for real time tracking of the drill bit.

Based on the experience with installation of the horizontal injection wells under the building, proposed installation of a row of 8 vertical injection points each with 8 feet of screen was abandoned in favor of installing a single horizontal injection well with 160 feet of screen. The comparison in favor of the horizontal injection wells was as follows:

- 150 percent more submerged screen length with horizontal injection wells.

- Distribution of additives across width of plume without gaps.

- Limited site disturbance to a 10 feet square patch with 60 feet trench to feed well head and avoided additional 160 feet of trenching for injection feed lines

- Single gravity feed point for simple and safer operation and maintenance

Flow Rates

When there were only 9 vertical injection wells (aggregate 45 feet of submerged screen) being fed by gravity, CLout® additive solution was being absorbed at the rate of 4,000 gallons per 14 to 21 days (0.9 – 1.3 gallons/hour/well). With the addition of the two horizontal injection wells, total submerged screen length for injection increased from 45 feet to 350 feet. When the two horizontal wells were brought on line with the gravity feed system, the 4,000-gallon tank was depleted within two days instead of the usual 14 to 21 days, seven times the vertical injection rate.

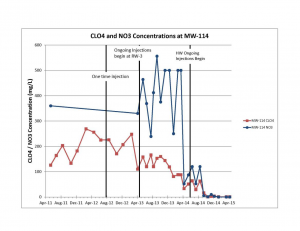

Perchlorate Concentration Reduction

In-situ treatment of perchlorate in groundwater with CLout® on a large scale 2-acre plume within a low permeability aquifer has been demonstrated with greater than 98 percent reduction of mass within a 3-year period.

Greener Cleanup Practices

The ASTM Standard Guide for Greener Cleanups E-2893-13 recognizes many aspects of this successful project as Greener Cleanup Best Management Practices, including the use of horizontal wells, gravity injection, and in-situ treatment.

Summary

This project demonstrates the major advantages of the ability of a CLout® injected through horizontal injection wells to expedite biodegradation of a large perchlorate groundwater plume. Several conclusions were determined from the project:

- The application of horizontal injection with treatment of a large perchlorate plume in groundwater accelerated the cleanup by several years based on segmentation of the plume under the building.

- 98 percent reduction of perchlorate mass was achieved within a 3-year period.

- The cleanup was effective in achieving residential soil standards and was closed without needing an Activity and Use Limitation.

- Implementation of in-situ treatment with CLout® using horizontal wells reduced the overall project cost by more than 60%, saving the responsible party over $5 million and at least 5 years of additional O&M compared to continuing with pump and treat.

- The site was recognized with an award by Mass DEP for Greener Cleanup Leadership in 2016.

Acknowledgement: IRWIN Engineers, J. Andrew Irwin, PE, LSP, AIrwin@irwinengineers.com