Not everybody is a fan of bugs; this is even truer for certain contaminants. Bioremediation is an excellent resource for cleaning up groundwater contamination, but in some situations, vertical techniques for this application fall short. Horizontal remediation wells precise installations and more screen in the target zone to get maximum contact between the injection amendment and the subsurface contaminants.

Bioremediation is an excellent method for remediating groundwater contamination. It involves injecting an amendment consisting of microorganisms or plants into the subsurface to biologically break down harmful substances into less toxic materials. However, the success of this application is contingent upon the successful dispersion of the amendment into the contaminated area. In many circumstances involving bioremediation, horizontal remediation wells offer many advantages over traditional vertical techniques to ensure a uniform and expansive injection.

First and foremost, horizontal wells allow the ability to reach contaminated zones that vertical wells cannot. Contamination often resides beneath existing buildings and can migrate with the flow of groundwater to exist beneath roads, storage tanks, and other surficial structures. Vertical drill rigs must be set up directly on top of the target area, making it difficult or impossible to reach these contaminated zones. During the drilling process of horizontal remediation wells, the bore path is tracked in real-time to ensure that the well screen will be expertly set within the target treatment zone.

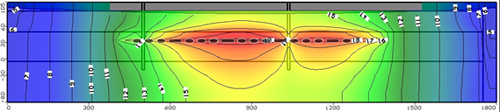

In order to create a successful bioamendment barrier in a traditional vertical remediation well design, the radius of influence must propagate far enough into the formation to overlap with the radius of influence of the adjacent wells in the barrier. Gaps in the amendment barrier provide conduits for contamination to seep through and continue downgradient. Horizontal remediation wells provide continuity across the well screen during the injection process and ensure that the treatment zone is effectively saturated with the remedial amendment.

Traditional in-situ bioremediation techniques, such as vertical well injections, often result in invasive designs and lengthy remediation timelines. Tens of injection wells, or more, may be required in order to inject the proposed amendment volume. One horizontal remediation well can often replace several vertical wells in order to remediate the same target area, eliminating unnecessary additional well construction in the subsurface and obstructive well vaults at the surface.

Source-area contamination is often difficult to reach, and without intercepting the proper preferential pathways vertical wells can struggle with delivering the full amendment volume. If time and efficiency are important factors when applying bioremediation at your site, horizontal remediation wells are the preferred method to achieve your project goals.

77 N. Plains Industrial Road

Wallingford, CT 06492

Over 5,000 Horizontal Remediation Wells Installed Worldwide

NAICS Codes: 237990 Heavy Equipment & Horizontal Drilling • 237110 Water & Sewer Line and Related • 541620 Environmental Consulting Services for HRW Screen Design • 237130 Underground Cable Lying & Utility Line Construction

Copyright 2025 Directional Technologies, Inc. All Rights Reserved.