Why are so many large petroleum cleanup sites looking at horizontal biosparging technology? Results!

Due to the successes of Horizontal Biosparge Wells, many large oil and gas companies are looking at this technology to address impacts on their large and busy sites.

They are choosing to use Horizontal Biosparge Wells for the following benefits:

- Lower flow rates = lower operations and maintenance (O&M)

- Horizontal Biosparge Wells can eliminate the need for vapor extraction, due to low flow rates

- Even at lower flows, Horizontal Remediation Wells can cover large areas, so significant volumes are still being added;

more dissolved oxygen = more food for the bugs - Proven ability to destroy large free product plumes

- Custom-designed horizontal well screens for even distribution can cover hundreds to 1,000+ feet

- All the other advantages gained from directional drilled horizontal wells, such as:

Minimize business disruptions - Avoid surface obstructions

- Save on costs of connective trenching, piping, and restoration

The reason behind the success is because the primary means of remediation is through the biological activity of indigenous microorganisms, biosparging is easier on the pocketbook than a traditional air sparging system. While air sparging removes constituents primarily through both volatilization and biodegradation, biosparging promotes biodegradation of constituents rather than volatilization, generally by using lower flow rates than are used in air sparging (EPA 1994). These lower flow rates result in less O&M and can eliminate the need for vapor extraction wells, which would typically be required to capture off-gassing from an air sparging system.

Biosparging technology can be further enhanced when applied through Horizontal Remediation Wells. Since horizontal well systems typically have 4 to 10 times more screen footage in contact with the contaminated media than vertical systems, Horizontal Biosparge Wells can inject much greater volumes while maintaining the same low flow rates. This, in turn, leads to more rapid increases in dissolved oxygen and aerobic biodegradation. In addition, these larger injection volumes have proven HBS well systems to be a viable treatment technology for large free product plumes.

In one example, 12 Horizontal Biosparge Wells with a total of 2,659 feet of horizontal well screen were installed to remediate the release of approximately 50,000 gallons of NAPL at a bulk petroleum terminal in the Northeast. The system was chosen as an alternative to a vertical biosparge system that would have required 129 wells with 272 feet of screen. Prior to the horizontal system installation, various remediation techniques, including excavation, soil vapor extraction, air sparging, oil skimming and total fluid extraction with vertical wells were able to recover approximately 19,000 gallons of TPH.

After eight years of operation, the Horizontal Biosparge Well system was able to eliminate over 30,000 gallons of TPH and reduce the free-product thickness from 2.3 feet to essentially a sheen.

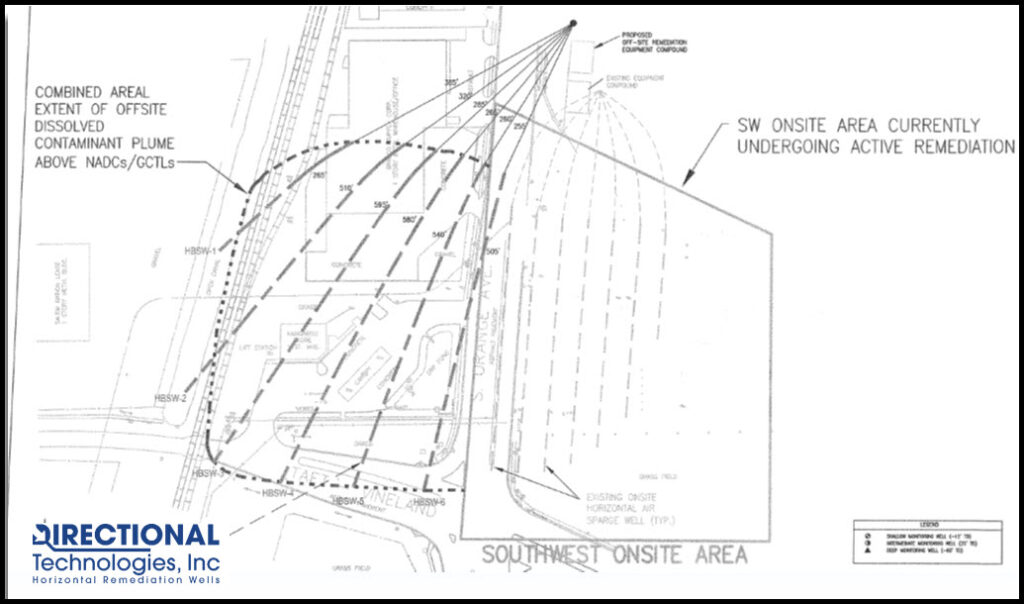

This figure is an example of another horizontal biosparge application. At this site, the Horizontal Biosparge Wells stretched across a 4-lane road and underneath a building materials warehouse and an operating gas station.