Horizontal Groundwater Extraction Wells were recently selected by a client to expedite cleanup and attain remedial goals. The installation, conducted by Directional Technologies, relied on accurate data, a well-planned design, and experienced technical decisions in the field. The Horizontal Remediation Well system successfully achieved performance goals for groundwater extraction and optimal yield.

A client was recently challenged with enhancing the effectiveness of a remedial treatment system. Impacts were along a thin layer of gray fine silty sand, directly above bedrock. After a thorough evaluation, Horizontal Remediation Wells (HRWs) for groundwater extraction were selected to expedite cleanup and attain remedial goals. Horizontal Remediation Wells provided a greater capacity to recover groundwater in the required thin target zone.

Volatile organic compounds (VOCs) in groundwater were captured by an existing remedial extraction system. The main remedial objective for installing Horizontal Remediation Wells was to supplement and enhance groundwater recovery for this existing remedy.

Directional Technologies installed two horizontal groundwater extraction wells using entry/exit installation methods. The two Horizontal Remediation Wells were composed of 4 inch PVC with 120 feet of horizontal screen set at a depth of approximately 30 feet below ground surface.

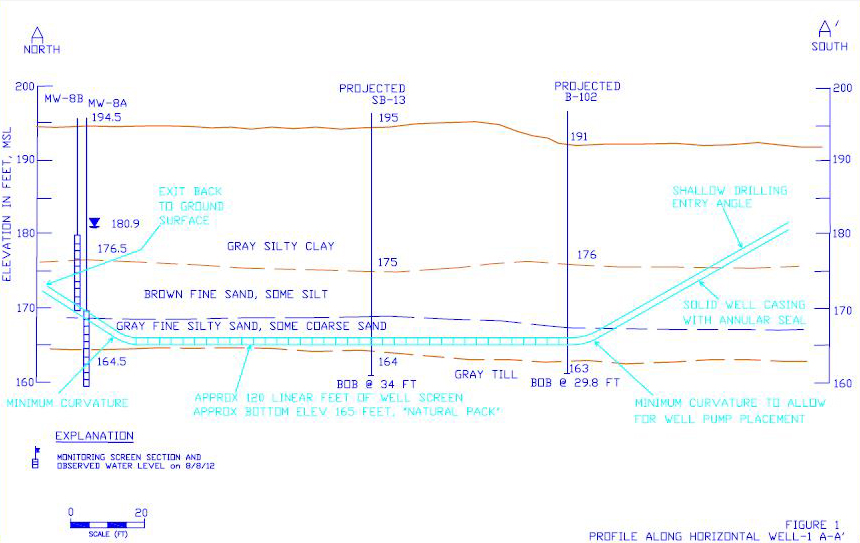

The targeted geologic layer consisted of gray fine sand and silty sand with some coarse sand, directly above bedrock. A cross-section diagram showing the subsurface geology and anticipated horizontal well screen position for one of the Horizontal Remediation Wells is shown below.

Cross-Section for Horizontal Groundwater Extraction Well System

The entry and exit locations were strategically located for ideal placement of the Horizontal Remediation Wells. At the north end, the ground surface was approximately 5 to 8 feet lower in elevation and wooded, compared to the open area to the south. At the south end of the horizontal well alignment, access was granted from an open parking lot. The entry angle was also selected to optimize the Horizontal Remediation Well installation, while accommodating surface completion requirements. The photo below shows the layout for these horizontal groundwater extraction wells.

Layout for Horizontal Groundwater Extraction Well System

Real-time analysis of the soil cuttings, separated from the drilling fluid returns, was used to make field adjustments of the drill path. Along with the constant tracking of subsurface conditions, the DTI drilling team ensured that the horizontal wells were placed accurately in the thin target layer. An effective working relationship between the consultant and DTI proved vital in delivering a horizontal drilling solution with very close tolerances.

After the HRW installations, extensive horizontal well development was performed to ensure a quality return permeability from the formation through the wellbore. This process includes dispersing residual drilling fluids, removing fine materials, and displacing the wellbore to clean fresh water. The installation relied on accurate data, a well-planned design, and experienced technical decisions in the field to successfully achieve performance goals for groundwater extraction and optimal yield.