Catering to the unique needs of the client and working hand-in-hand with the consultant, Directional Technologies approached a challenging remedial situation with flexibility and a new approach to re-task a horizontal injection well system to horizontal recirculation wells.

A property owner inherited an estate that needed a rapid site closure technology to remediate under buildings to ensure full market price for a sale. The property suffered impacts from leaking fuel oil and the consultant sought horizontal wells for bio-amendment injection. The original purpose of the horizontal wells was for injection only. However, as the project progressed and as the horizontal wells were being installed, a greater level of contamination was encountered. Flexibility and a new approach were required.

Midway through the project, Directional Technologies and the consultant worked together as a team to re-task the horizontal injection system into a horizontal recirculation system. The pair of horizontal wells was reviewed to make sure they could be engineered to work together, one injecting and one extracting, with an isolated zone in each well.

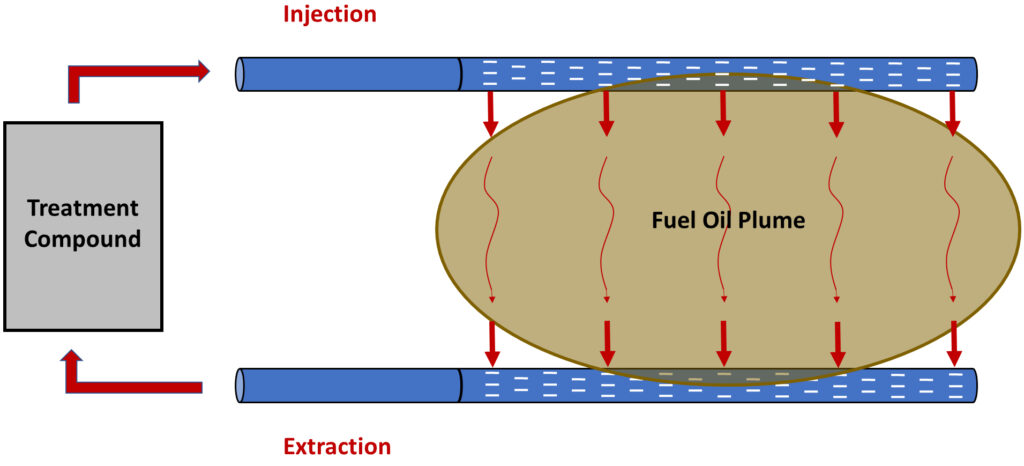

Diagram of Horizontal Recirculation Wells System

The treatment involved the extraction of groundwater, which was treated with bio-amendments and reinjected. This flow pattern created a recirculation gradient across the plume. Additional engineering was added to the horizontal well screen so that the wells were pumped and injected in discrete zones along the length of the wells allowing for the areas which had higher concentrations of fuel oil to receive more treatment.

This project benefited from decades of horizontal well installation experience and was able to:

- Cater to the unique needs of the situation by quickly and flexibly switching gears from a horizontal injection to horizontal recirculation system

- Work closely with the consultant and the client to redesign the project, while simultaneously installing the first horizontal well

- Accelerate cleanup and exceed the client’s remedial objectives

So Why Directional Technologies?

Each project builds our knowledge for the next, refining our process through successes and site-specific challenges. If we were presented with that same situation today, we would have even further capabilities and value-added design suggestions.