Residents benefit from installation of horizontal groundwater extraction well to recover carbon tetrachloride from a bedrock aquifer.

Contamination beneath a residential area is always a sensitive situation for all parties involved. Horizontal remediation wells provide many benefits in these scenarios. This case study discusses how a horizontal groundwater extraction well helped remediate an extensive carbon tetrachloride plume beneath multiple residences and a recreational area.

Background

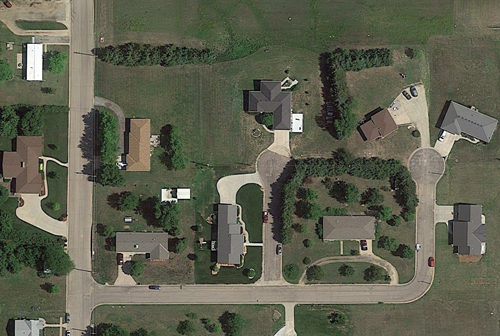

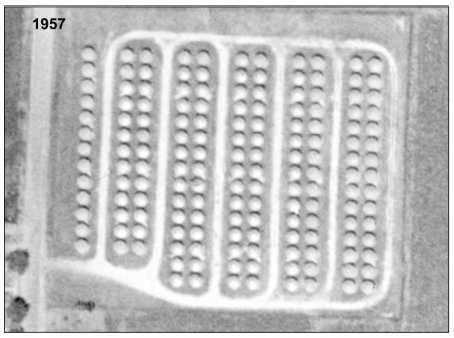

In a small farming town of in the Midwest, a grain storage facility, which operated from approximately 1950 to 1976, used fumigants comprised partially of carbon tetrachloride to preserve harvested grain. In 1978, the facility was no longer in use and the area was redeveloped as a residential zone with nine homes eventually built on top of the former facility.

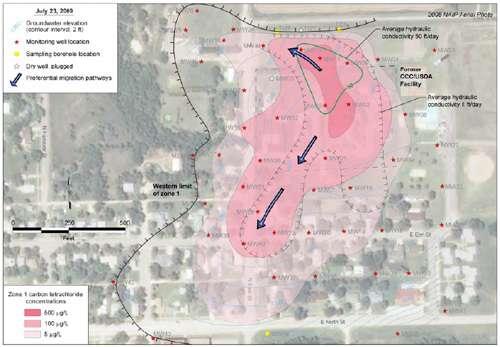

In 1998, the United States Department of Agriculture (USDA) funded a private water well sampling program which identified carbon tetrachloride impacted groundwater in water bearing zones beneath the residential development. Subsequent soil and groundwater assessment of the site and surrounding area revealed the highest concentrations of carbon tetrachloride [greater than 500 micrograms per liter (µg/L)] were beneath the north-central portion of the former grain storage facility, now redeveloped with residences.

Vapor intrusion assessments of the residences were conducted in 2007. Five homes were identified to contain indoor air concentrations of carbon tetrachloride above the state’s regulatory levels. To immediately address this issue, vapor mitigation systems were installed in each of the five residences. However, the long-term threat of future exposure pathways remained as long as the contaminated groundwater was present below the residential area.

Corrective Action Study

The USDA funded a study to determine the best approach to prevent the long-term exposure threat to the public. Considerations included:

- No further action;

- Municipal land use controls and well abandonment; and

- Targeted groundwater extraction.

In 2013, the Final Corrective Action Study stated: “The preferred remedial alternative selected is the installation and operation of a groundwater extraction system consisting of a horizontal extraction well installed in the more permeable, highly contaminated portion of groundwater. The groundwater extraction provides for significant mass removal from the most contaminated portion of Zone 1 and for active reduction of the carbon tetrachloride concentrations, thereby reducing the risk of potential vapor intrusion.”

A network or linear path of vertical groundwater extractions wells and connective piping was deemed to be too invasive to the residents. In addition, gaps in the influence of the extraction wells would be present beneath residences where vertical wells could not be installed.

Therefore, the corrective action study recommended installation of a horizontal groundwater extraction well, installed in the highest impacted zone of groundwater.

Site Geology

The region is underlain by unconsolidated Pleistocene eolian (wind-blown) silt and alluvial sediments from nearby floodplain of a meandering river. These deposits overly weathered shale and interbedded limestone and shale. Groundwater occurrence is present within a few discrete, thin saturated zones with a total combined thickness of 1 to 3 feet. The average permeable velocity is calculated to be approximately 14 feet per year.

Horizontal Extraction Well Design and Installation

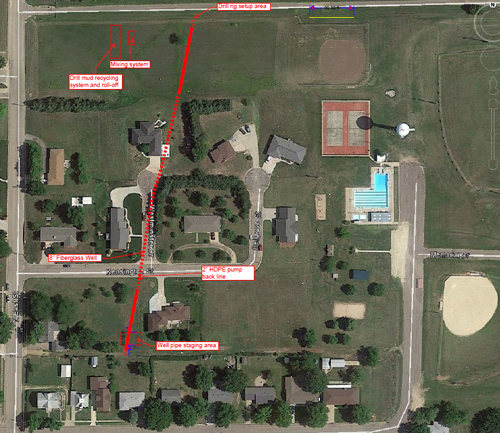

The horizontal extraction well was constructed of 8-inch diameter HDPE riser pipe, with 450 feet of 6-inch diameter fiberglass screen with machined slot opening size of 0.02 inches. The target depth of the horizontal well was approximately 32 feet below ground surface (bgs). Two submersible pumps designed for horizontal wells were installed in both the ends of the horizontal well. The pumps transfer the contaminated groundwater to a diffused aeration tank stripper for treatment prior to discharge.

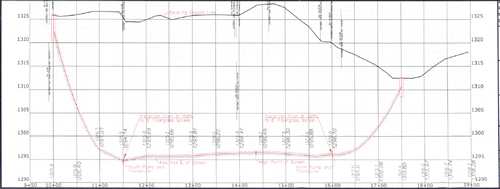

The goal of the horizontal extraction well was to provide an estimated 100-foot radius of influence outward from the centerline of the horizontal screen to create a trough of depression to cover most of the impacted groundwater zone.

The anticipated duration of remediation was estimated from 1.8 to 5.4 years based on the known pore volume permeability of the aquifer and an average flowrate of approximately 2 gallons per minute.

Directional Technologies mobilized to the site in 2017 for the installation of the horizontal groundwater extraction well. Due to the target depth of 32 feet below ground surface, the horizontal bore required entry through unconsolidated soils and then into weathered bedrock. Multiple types of directional drilling tools were required to complete the pilot bore and successfully install the horizontal well.

Horizontal groundwater extraction well startup and performance

The horizontal groundwater extraction system was activated in September 2017. The combination of the two submersible pumps provided initial flow rates of 2 gpm as designed. Once the groundwater is treated within the air stripping unit, the water is permitted for re-use for irrigation of local agriculture, benefiting the community.

Research Source

Final Corrective Action Study for the Form CCC/USDA in Hanover, Kansas. Argonne National Laboratory, Applied Geosciences and Environmental Management Section Environmental Science Division. November 2013. Interim Corrective Action Report. Chase Environmental Group, Inc. January 2018