Horizontal Wells bring value to your clients. It is not accurate to compare a horizontal well to a vertical well on a per foot basis without considering other remedial construction costs tied to vertical installations. Actually, if you compare horizontal to vertical installations based on total remediation costs, horizontal wells are typically less expensive.

Vertical wells have substantially more costs that clients sometimes forget when comparing well installation costs. To name a few, this includes more site restoration, interconnecting vertical wells, trenching for vertical wells, and more areas to clear for utilities due to the greater number of vertical wells needed.

The savings and reduced remedial construction costs should be factored into a remediation cost comparison to accurately evaluate Horizontal Remediation Wells.

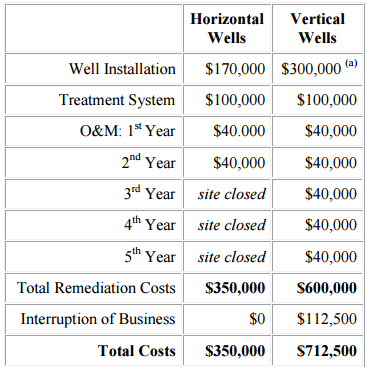

Recently, a client saved $362,500 in project costs by installing Horizontal Remediation Wells instead of vertical wells. Besides avoiding a business loss of over $110,000 during construction of the remedial system, the client avoided $130,000 in trenching and soft dig costs to install and connect vertical wells to the same remedial system. Another benefit that the client realized was saving $120,000 in remedial system Operation & Maintenance (O&M) costs. The remedial system with vertical wells was estimated to run for five years. The same remedial system with horizontal wells attained cleanup goals in just over a year of operation.

Cost of Horizontal versus Vertical on Medium-Size Cleanup

Note: (a) includes trenching for connections

When overall remedial system costs are compared between vertical and horizontal remediation systems, Horizontal Remediation Wells are less expensive and achieve remediation faster. Therefore, this remediation approach adds value to your client through cost savings and less disruptions on your project site.

Summary of Advantages

♦ HRWs avoid costly trenching

Where multiple vertical wells with short 10 foot well screens need to be interconnected, a few horizontal wells with hundreds of feet of well screen can cover the area of treatment without trenching. Also, there is limited to no conveyance lines and piping.

♦ HRWs can directionally steer to one vault location

One horizontal vault vs. multiple vertical vaults allows easier access and more efficient remedial system O&M.

♦ HRWs avoid disrupting businesses and operations

Operations can continue without loss of revenue. Workers are not displaced, vehicles are not stopped or redirected, and critical business can continue.

♦ HRWs have substantially more screen for faster cleanup

Horizontal well screens strategically target the zone of treatment. HRWs increase the amount of screen at the source. More Screen = More Treatment

PDF: HRWs Bring Value