Frequently asked questions about Horizontal Wells and Directional Drilling

When directional drilling a horizontal well, how do you steer the drill bit? And, how accurate is the tracking?

Answer: Directional Technologies’ locator uses equipment that sends a signal from inside the drill bit to his equipment on the surface. The locator then directs the directional drill operator to turn the drill bit any number of varying degrees to achieve the required depth, pitch, and direction. This is how we do it, watch this Directional Drilling Video

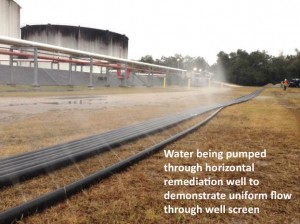

How is uniform flow ensured through the horizontal well screen?

Answer: Each project is unique, DTI custom designs each horizontal well accordingly. Depending on the horizontal well length, slot size and spacing are manipulated in such a way that ensures even flow distribution.

Answer: Each project is unique, DTI custom designs each horizontal well accordingly. Depending on the horizontal well length, slot size and spacing are manipulated in such a way that ensures even flow distribution.

Do we have any “No Further Action” sites?

Answer: Yes, many sites where DTI has installed horizontal wells, whether they are utilizing air sparge/soil vapor extraction, sparge, chemo injection, or total phase extraction, are closed. Typically, sites that use Horizontal Remediation Wells (HRWs) clean up much faster than sites utilizing traditional vertical wells. Remediation plans utilizing vertical wells suffer from limitations on to many sites where access was not feasible due to the presence of buildings, roadways, etc. in relation to the contaminated plume. These limitations can make it difficult or impossible to apply any chosen remediation technology to the entire contaminated zone, making complete source treatment difficult or impossible. Horizontal wells can get right to the targeted zone beneath existing site restrictions. Additionally, HRWs have significantly greater well screen in contact with the impacted media. The Radius of Influence (ROI) that can be achieved with an HRW is markedly, and sometimes astonishingly greater than what can be achieved utilizing vertical wells. The can lead to a much shorter time frame until site closure goals are achieved.

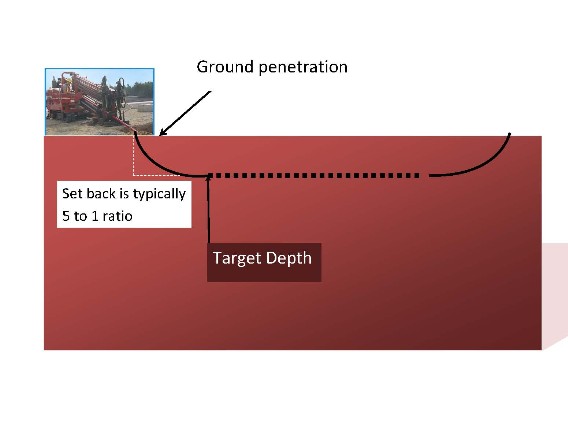

How deep can a horizontal well be installed?

Answer: There are two factors to keep in mind when planning and considering a deep horizontal well: setback and cost. For each horizontal well, a setback distance is needed. Setback is the distance required from ground penetration to target depth. The typical setback ratio is 5 horizontal feet of set back for every foot of vertical penetration. Cost is a factor when the horizontal well requires locator instrumentation other than the traditional walkover locator; typically this is at depths of about 100′ below ground surface or where there are complicated or mass underground features below the ground surface. Read our full article: How deep can a horizontal well be installed?

More questions? Email us at drilling@directionaltech.com

More questions? Email us at drilling@directionaltech.com