An environmental well installed by Directional Technologies for leachate collection using horizontal development techniques achieved well yield increase by 600% at a Superfund site in New Jersey.

Yellow line indicates Horizontal Well bore path around perimeter of site

A site management, design and operation team, in coordination with State and Federal regulators managing a Superfund site determined that a portion of the existing vertical groundwater recovery/hydraulic control network was failing. The high mineral content and fine-grained formation were causing numerous problems, which were reducing the effectiveness of the network. Remedial alternatives were reviewed, including a one-pass trenching and underdrain installation process, but upon further review of the site remediation objectives, it was determined that a Horizontal Remediation Well would be the most effective choice. The environmental well would be installed at a depth of 36’ below ground surface.

Directional Technologies’ environmental directional drillers installed an 800’ long landfill leachate collection well to ensure the protection of off-site potential receptors. The environmental well was designed to be equipped with a pumping system to collect the leachate. The well included chlorinated solvents, as well as other typical municipal landfill leachate constituents. The leachate would be pumped to an on-site pretreatment facility, prior to discharge to a publicly owned treatment facility (POTW).

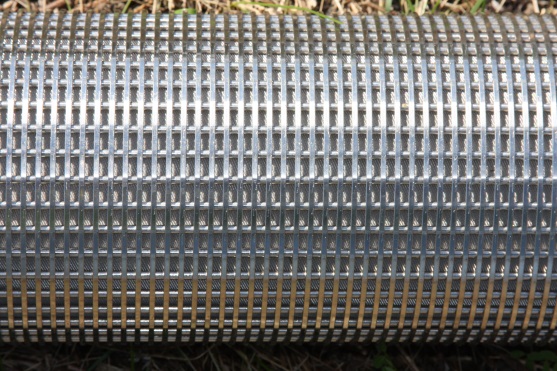

The horizontal well screen and casing consisted of 20′ welded stainless steel sections. The sections were delivered to the site and welded prior to subsurface installation.

Custom Stainless Steel Environmental Well Screen

Before initial development to remove drilling fluids began, it was determined that due to the characteristics of the formation and the type of screen selected, the well would require additional development to achieve its full potential. DTI ‘s environmental drillers utilized their extensive experience in horizontal well development techniques to increase the well yield by 600%.

Additional testing of the horizontal well to determine the radius of influence (ROI) indicated an extensive trough of depression along the 500’ screened section. Monitoring wells located approximately 50’ down gradient from the horizontal well showed approximately 1’ of drawdown influence within an hour of initiation of the test.

DTI’s experience in the oil field, environmental remediation and utility industry allows the company to complete projects that were previously considered unfeasible.