Successful pilot testing in North Carolina saprolite leads to full-scale implementation of horizontal remediation of trichloroethene (TCE)

At Directional Technologies, Inc., we learned a valuable lesson a long time ago from the project described below: “Don’t judge a site by its soil!” The consultant had the vision that horizontal wells were the right application for the site, and in the process, expanded the industries’ knowledge, geographic coverage, and experience of in-situ remediation in saprolite and similarly tight soils.

This project dramatically changed the way we view and evaluate projects and how horizontal wells can be applied for those difficult sites that seemed impracticable to conventional solutions.

Background

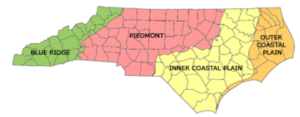

The Piedmont geographical region in North Carolina is mostly underlain by saprolite, a clay rich soil formed by the in-place weathering of igneous and metamorphic bedrock. Saprolite is routinely a challenging substrate for in-situ remediation of soil and groundwater contamination.

One such site which required in-situ remediation of primarily trichloroethene (TCE) was located in the town of Asheboro in Randolph County, North Carolina. When Directional Technologies, Inc. was asked to visit the site prior to installation of horizontal wells for a pilot study and saw firsthand the type of soil that the wells were to be installed, we were skeptical that horizontal wells were the right application for the site. But after further discussion with the consultant, a sound argument was made that pathways existed in the soil that transported the TCE from under the building to a creek which traversed behind the building. The consultant hypothesized that the best remedial approach was to use horizontal wells to intersect the pathways to create conduits for air movement from a remediation system.

Pilot Test Activities

DTI installed one horizontal air sparge well and one horizontal soil vapor extraction well beneath the manufacturing building for the pilot test which lasted four days. Results from the pilot testing indicated that the tight saprolite takes time to develop. The horizontal SVE wells were successful by reducing the moisture content in the soil within the vadose zone, gradually creating air movement through the former fractures of the weathered bedrock. The air sparging also successfully developed a radius of influence over time, proving the consultant’s theory correct, that the air movement would eventually find the same pathways which the TCE impacted groundwater had previously followed. Based on the results of the pilot study, a full-scale design was developed with engineered horizontal well screen.

Conclusion

If a vertical AS/SVE system were designed for this project, multiple vertical points would have been required within the building, along with all the trenching for connection piping. Additionally, this work would have been performed with no guarantee that the vertical points would intersect the subsurface pathways. Horizontal wells significantly increased the probability of intersecting the preferential pathways within the saprolite where vertical wells would be hit and miss.

Since the time of this project many years ago, Directional Technologies, Inc. has installed thousands of feet of wells in similar conditions with great success. Let our experience and lessons learned benefit your next project. We have installed horizontal wells across the United States, and internationally. There is rarely a site scenario or subsurface condition that we have not previously encountered and found a solution.

Contact us to discuss your project and explore horizontal remediation well applications for your site.