This paper discusses various aspects of soil vapor intrusion, why it is a major concern and concludes with details on how horizontal remediation wells can be very effective and economical mitigation solution.

What Is Soil Vapor Intrusion?

Soil vapor Intrusion is an environmental exposure pathway, a way that people can come in contact with environmental contaminants. Vapor Intrusion exposes building occupants to potentially toxic levels of vapors when volatile chemicals (those that readily evaporate) present in contaminated soil or groundwater emit vapors that migrate into overlying buildings.

Why Is Vapor Intrusion The “Overlooked Environmental Pathway”?

For many years the environmental remediation profession was inadequately informed that volatile chemicals in vapor form could migrate through the subsurface and into buildings. In recent years, the US Environmental Protection Agency (EPA) and many state environmental regulatory agencies have conducted campaigns to inform both the remediation profession the general public about Vapor Intrusion risks.

Why Is Vapor Intrusion A Concern?

In more extreme cases, the vapors may accumulate in dwellings or occupied buildings to levels that may pose near-term safety hazards (explosion), acute health effects, or odors. Typically, however, the chemical concentrations are low or, depending on site-specific conditions, vapors may not be present at detectable concentrations. In buildings with low concentrations of volatile chemicals, the main concern is whether the chemicals may pose an unacceptable risk of chronic health effects due to long-term exposure. A complicating factor in evaluating the potential chronic risk from vapor intrusion is the potential presence of some of the same chemicals from emission sources in the building, such as household solvents, gasoline and cleaners that may pose, separately or in combination with vapor intrusion, a significant human health risk.

A Closer Look at Soil Vapor Intrusion

Vapor intrusion can happen when volatile or semi-volatile chemicals in soil or groundwater migrate toward buildings and enter through cracks and openings in the foundation. Inhaling these vapors may cause both chronic and acute health effects. The potential for vapor intrusion can exist even though industrial activities may have never occurred on a property – vapors can migrate considerable distances under the right circumstances.

For the remainder of this discussion, we will describe chemicals that may result in vapor intrusion as volatile organic compounds, or VOCs.

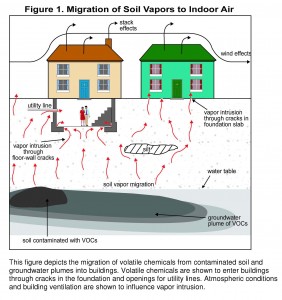

As illustrated in Figure 1, VOCs in contaminated soil and groundwater emit vapors that rise through the pore space of the unsaturated zone above the water table. Where bedrock underlies a property, the vapors move through fractures and openings in the rock.

These vapors, also known as soil gas, can move laterally as well as vertically from the contamination source. Lateral movement can increase as groundwater plumes migrate away from the contamination source or if the ground surface is paved or frozen, which prevents vapors from escaping upwards.

Soil gas movement is controlled by the processes of diffusion, meaning that concentrations tend to be higher near the contamination source and lower near uncontaminated areas. Soil gas movement can also be controlled by advection, which is the movement of soil gas from areas of higher to lower pressure.

As diffusion causes vapors to rise through soil or bedrock, they tend to accumulate under building foundations and other barriers such as pavement. These barriers create a capping effect, which inhibits upward movement of vapors. Because of cracks and other openings in building foundations, these barriers are not impenetrable. Vapor intrusion generally occurs when advection (movement due to pressure differences) draws vapors into buildings via these openings.

The pressure beneath a building is typically higher than the indoor pressure due to a phenomenon called building depressurization. Depressurization tends to causes buildings to draw soil gas inside. Soil gas that does not pass within the building’s zone of influence will continue migrating within the subsurface or escape to the atmosphere. Vapors that pass within the building’s zone of influence tend to be drawn in through foundation cracks or through other penetrations.

Depressurization is caused by leaky HVAC systems, exhaust fans and stack and/or wind effects (see Figure 1) that tend to reduce indoor pressure. Stack effects cause building depressurization as a result of differences in indoor and outdoor temperatures. As warmer indoor air rises and exits through the building’s upper elevations, the resulting pressure differential can induce vapor flow into the bottom of the building. Stack effects can transport vapors to a building’s upper floors via stairwells, elevator shafts, ductwork, etc. Wind currents passing over a building can also induce pressure differentials that can affect the vapor flow into a building.

VAPOR INTRUSION MITIGATION

Whether existing structures will be renovated or new buildings constructed, vapor intrusion can be mitigated at contaminated sites. Eliminating the contamination source can be more protective of human health and the environment than mitigation alone, but it is generally time-consuming, sometimes taking many months or years. Therefore, vapor mitigation is often specified as part of the remediation process.

Vapor intrusion mitigation systems can be active or passive (energy is or is not imparted to remove vapors, respectively). This discussion limits itself to active pressure-reducing mitigation systems for the industrial, commercial and retail sectors.

Active Soil Vapor Intrusion Mitigation Methods

Active approaches to mitigating vapor intrusion remove the driving force behind vapor migration – the higher pressure that exists in the subslab. By lowering the sub-slab pressure vapor flow is neutralized or reversed.

Subslab Depressurization: Subslab (below the floor) depressurization systems involve two basic components: slotted pipes to evacuate the soil vapor from beneath the building’s concrete floor slab and a fan to induce negative pressure. Slotted pipes have historically consisted of shallow vertical wells advanced through the building’s floor using a conventional drill rig. Trenches are excavated, interconnecting piping is installed to connect the wells, which are then connected to a fan.

There are significant disadvantages associated with vertical vapor intrusion mitigation systems. The primary disadvantage is business interruption, many times for weeks, while the wells are advanced through the floor and the interconnecting piping network is installed. This can be prohibitively expensive and sometimes infeasible. Another disadvantage of considerable concern is the potential for “dead spots” between vertical wells. In other words, if the vertical wells are not properly spaced such that there are overlapping zones of influence, there could be areas where there is no negative pressure when the system is operating. Vapors could potentially continue to migrate into the building in these locations.

How Are Horizontal Remediation Wells Superior When Used In Vapor Mitigation?

Horizontal Remediation Wells are superior because they have significantly greater zones of influence versus their vertical counterparts. It is not unusual for a Horizontal Remediation Well to have a zone of influence of 100 feet (or greater) on either side of the well screen. This means that it is highly unlikely for dead spots to exist.

Another important element contributing to the superior performance of Horizontal Remediation Wells is that when properly designed they can be “dual-use”, meaning that they can be initially used as conduits to inject chemical products to enhance the naturally occurring bacteria that drive bioremediation processes, thereby accelerating the overall remediation process.

A significant differentiator is that Horizontal Remediation Wells can be installed with no business interruption. The Directional Technologies crew places the horizontal drilling rig in a convenient non-intrusive outdoor location. The horizontal bore is advanced from one location without the need to enter the building. Very large structures may require multiple Horizontal Remediation Wells. In many cases, it is feasible to install multiple Horizontal Remediation Wells from one drilling location.

Please contact Directional Technologies, Inc. at 203-294-9200 for additional information regarding the benefits of Horizontal Remediation Wells!

(Source: The 2008 Brownfields Technology Primer: Vapor Intrusion Considerations for Redevelopment, EPA 542-R-08-001.)