Targeting non-aqueous phase liquid (NAPL) hotspots with horizontal remediation wells is an effective way to enhance remediation and prevent downgradient plume migration. Groundwater contamination plumes sometimes separate into several individual zones, creating additional challenges for remediation and increasing the likelihood of off-site migration. Lithologic variations can cause the groundwater to transport the contamination through preferential pathways, breaking off from the main plume and creating individual hotspots of elevated levels beneath a site. Additionally, if NAPL is present, it can remain trapped in the vadose zone. False impressions of contamination reductions in the groundwater can be documented as contaminants adsorb to the soil during lower water levels. As levels rise, those contaminants are reintroduced to the groundwater, elevating contamination levels and allowing the contaminants to become mobile again. In the case study below, a series of horizontal soil vapor extraction (SVE) and air sparge (AS) wells were installed to target groundwater contaminant hot spots and also create a barrier to prevent migration of groundwater contamination beneath a redevelopment site in California.

Problem: Migration beneath a redevelopment property

A site in California was experiencing a migration of off-site groundwater contamination onto a future redevelopment property, which required the simultaneous execution of preventing further migration and reducing groundwater contamination levels on-site. Several existing facilities and storage tanks on the property contained the presence of non-aqueous phase liquid (NAPL) beneath them. A network of associated utilities was on site, along with several vertical monitoring wells scattered across the property, which could not be impacted during the installation of the horizontal remediation wells. Due to access constraints at the site, horizontal drilling was proposed to install screened remediation wells for a combination of SVE and AS systems in lieu of traditional trenching.

The plume separating into individual hotspots required design ingenuity to keep well construction materials and associated costs low while providing maximum screen access with the contamination in both the vadose zone and below the water table. Using horizontal drilling and installation techniques, on-site disturbances of commercial activities on the property could be minimized during all phases of the remediation process.

Solution: Designing a Successful Horizontal Remediation System

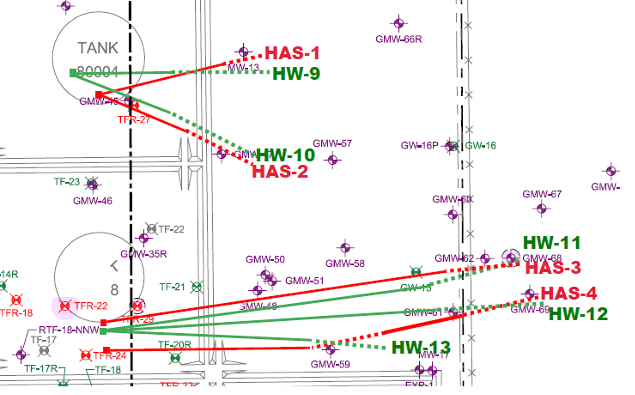

Directional Technologies teamed up as a collaboration partner to help design and implement a horizontal remediation system that would meet the remedial goals of the project. The primary objective of the horizontal system was to target the NAPL hotspots beneath the existing on-site facilities while simultaneously creating a hydraulic barrier to prevent further migration of the contamination. DTI installed four horizontal SVE wells and four horizontal AS wells to address the contamination at the site (Figure 1). The horizontal SVE wells ranged in length from 260’ to 600’ in length, set at a depth of 30’ below ground surface (bgs). The AS wells were between 330’ and 550’ in length and were set at a depth of approximately 43’ bgs, below the water table. To target the NAPL below the existing obstructions, the horizontal wells were installed using blind installation technologies, meaning only an entry point was required, with the well terminating at the end of the screen below the ground surface. Blind installations are particularly useful at site locations such as this, where on-site obstructions prevent access to the contamination.

The wells were installed with varying screen lengths to target the specific locations of NAPL within the subsurface. However, there were instances where multiple NAPL hotspots existed within the trajectory of one horizontal remediation well. To effectively target the individual zones, Directional Technologies provided an alternative well layout for HAS-4, which utilized a 2-zone continuous screen across the required regions. This way, each segment of the NAPL plume could be accessed without installing additional wells, providing monetary savings in addition to drilling footage and associated well materials. The off-site extent of the southern wells assisted in preventing the migration of contamination onto the adjacent eastern property that was scheduled for redevelopment.

Results:

Directional Technologies successfully installed a combination of horizontal SVE wells and horizontal AS wells despite the physical challenges presented at the site. Each well was successfully installed into the target NAPL hot-spot zones, providing the necessary remediation to eliminate the measurable product. The southern horizontal remediation wells provided the hydraulic barrier necessary to prevent contaminant migration onto the adjacent property that was to be redeveloped. When activated, the system’s design successfully addressed the main remedial concerns of reducing the NAPL presence at the site while preventing off-site migration of the contamination. Ultimately, the remediation allowed for the uninterrupted redevelopment of the adjacent property.

How can the advantages offered by decades of technological advancement in horizontal wells benefit your project? Call our horizontal remediation well experts at 1-877-788-4479 to discuss your current project needs or complete our form HERE!

Author: Elliott Andelman, Environmental Scientist