Investigating an unfamiliar technology can be intimidating, but exploring horizontal remediation wells (HRWs) with Directional Technologies, Inc. (DTI) is painless. DTI has a curated discovery process that is designed to provide you with answers to any questions you have about HRWs and evaluate how HRWs could help bring your site to closure. A phone call to Directional Technologies, Inc. (DTI) will put you in contact with one of our horizontal well experts, who is prepared to discuss your site at any stage of the process it is in, or simply answer questions you may have regarding horizontal technologies.

Personalized, Site-Specific Approach to Horizontal Designs

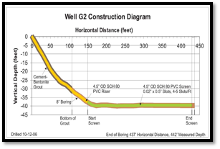

DTI takes a personalized, site-specific approach to all environmental projects, with the goal of partnering with environmental consultants to increase the remedial effectiveness at their site through the use of HRWs. Following the discovery call, DTI encourages supplemental conversations to discuss the physical features of the site, including the contaminants, subsurface geology, and the proposed remedial application. Each of these factors is considered when constructing the layout and screen design of the horizontal wells.

Planning the design of a remedial system can be daunting, particularly if the technology is unfamiliar. DTI has spent over 30 years pioneering horizontal remediation technology and has the knowledge to design the optimal layout for you, as part of our services. Customization, however, goes beyond the well layout. Since horizontal wells contain significantly more screen than vertical wells, it is critical that the screen is designed to optimize the remedial application. DTI has you, and your contamination, covered. Our proprietary screen-design software takes inputs from the physical aspects of your site, such as lithologic information and system requirements, and produces an optimized screen design that is unique to your site, ensuring uniform flow across the entire well. Remediation systems themselves vary from site to site, with different or reused equipment (blowers, pumps, etc.) selected for the remedial application at hand. DTI’s well screens are also designed to match the parameters of the system that is already on site, or on its way to the site.

Designs with “Success” in Mind

“Site-specific” is critical in terms of design, but a project’s success is equally driven by management-level logistics. Each project has different clients, regulatory agencies, and stakeholders, all with various ideas about what “success” looks like as it applies to your project. Success for the regulatory agency may depend on the technical aspects of the remediation, such as the volume of amendment injected or the radius of influence achieved, while success for the client may correlate to disruptions to their business during the implementation phase. DTI encourages site-specific conversations beyond technical details to fully understand what “success” means to all parties involved in the project. This way, there are no surprises for you or your clients by the time the boots are on the ground.

How can the advantages offered by decades of technological advancement in the field of horizontal wells benefit your project? Call our horizontal remediation well experts at 1-877-788-4479 to discuss your current project needs or email us at drilling@directionaltech.com with questions, review case studies, and learn more.

Author: Elliott Andelman, Professional Geologist