In-situ remediation through thermal methods can treat a wide range of contaminants, but only if there is enough contact between the piping and the contaminants. Horizontal wells and conduits can be installed with high precision over long lateral distances to ensure maximum exposure in the subsurface. No matter what shape the contaminant plume takes, horizontal wells have you covered.

The vaporized contaminants are then extracted and transported to a remediation system, where they are treated. In most cases where thermal remediation is taking place, the alternative would be to excavate the soil and transport it to a facility for ex-situ remediation. This can be an extremely expensive process and is not always feasible depending on the location of the subsurface contamination.

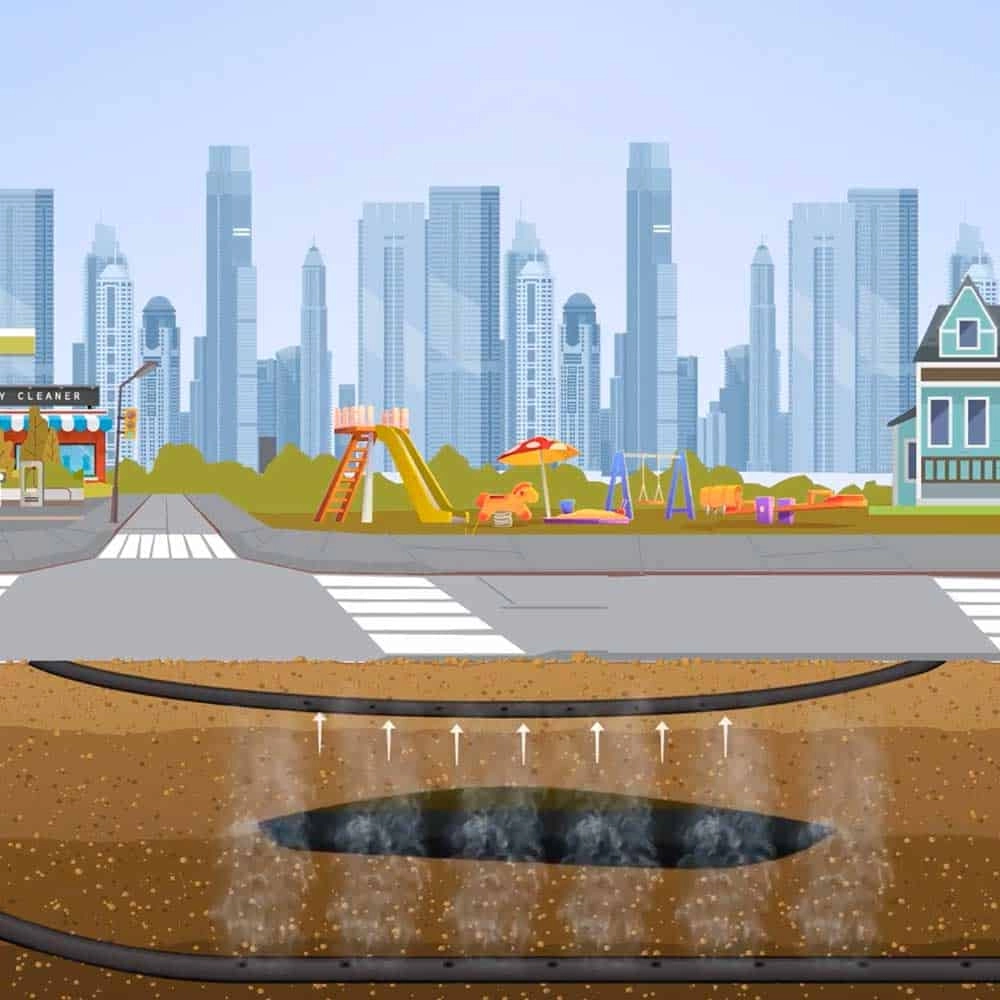

Whether the contamination is in a wide-open field or beneath an obstruction, such as a building, horizontal wells can provide direct and expansive coverage for thermal remediation. In a vertical setting, it may require tens or hundreds of thermal points spaced just a few feet away from one another to achieve the special influence necessary to heat up the target area. Just a few horizontal wells can replace several of these vertical points while providing enhanced thermal contact with the contamination.

Once the electrodes, heaters, or steam wells are installed in the subsurface, the energy costs to keep the system running can be extensive. Horizontal installations can help reduce costs by putting the conduits in direct contact with the contamination through horizontal directional drilling techniques. This is particularly useful at sites where the contamination exists as isolated hot spots, where one horizontal well can be installed to intercept multiple isolated pockets. With more well-to-contaminant interaction, the cost savings increase as more of the harmful chemicals are targeted at once.

Horizontal wells shine in their ability to access contamination in areas where traditional techniques have difficulties. Horizontal wells and conduits can be installed beneath buildings where source-area contamination is most common. Similarly, due to the precise navigational control of experienced directional drillers, subsurface obstructions such as utilities or underground storage tanks can easily be avoided, while still placing the thermal conductors where they need to be.

Through horizontal directional drilling techniques, various thermal remediation applications can be installed directly into the target zone. Through enhanced contact with the subsurface soil or groundwater contamination, volatilization takes place at a faster rate to save time and money on thermal projects.

77 N. Plains Industrial Road

Wallingford, CT 06492

Over 5,000 Horizontal Remediation Wells Installed Worldwide

NAICS Codes: 237990 Heavy Equipment & Horizontal Drilling • 237110 Water & Sewer Line and Related • 541620 Environmental Consulting Services for HRW Screen Design • 237130 Underground Cable Lying & Utility Line Construction

Copyright 2025 Directional Technologies, Inc. All Rights Reserved.