Wells are wells are wells, right? Both conventional vertical wells and directionally drilled horizontal wells have a screened casing that is connected to solid riser casing which leads to the ground surface. Groundwater or soil vapor is drawn through a well screen to remove contaminants. Remediation agents such as air, bioamendmnents or potassium permanganate are injected through a well screen to treat contaminants in situ. This is where the similarities end.

There are some important practical benefits of horizontal wells, independent of the remediation strategy.

- Horizontal wells can be installed in areas with subsurface obstructions such as utilities and under buildings, lagoons, wetlands, railroad tracks, etc. Directional drilling makes it possible to install wells where vertical drill rigs have no access.

- Natural flow patterns in typical soil strata tend to create plumes that are much longer and wider than they are thick. Horizontal wells can therefore be favorably oriented to take advantage of plume geometry and flow direction. This allows horizontal wells to achieve greater efficiency of delivery or recovery than vertical wells in many hydrogeologic settings.

- Accurate installation with respect to elevation and location allows for efficient recovery of LNAPLs, but the well placement must take into account fluctuations in the water table. Installation along the base of aquifer allows efficient recovery of DNAPLs and prevents further downward migration through the confining layers.

- Because of the larger screen area in contact with the impacted media, fewer wells may be needed, and therefore fewer pumps, less piping, and lower operation and maintenance costs. Horizontal wells can be drilled and completed while normal site business continues without interruptions.

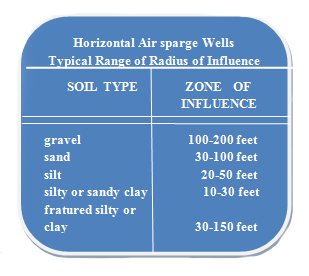

- Horizontal wells have a longer screen interval in contact with a larger mass of contaminated media. This results in a greater zone of influence and more efficient remediation. The table below describes the typical zones of influence for common subsurface conditions and this generally results in shorter time of operation and quicker cleanup.

Horizontal well technology can be adapted to many in situ remediation techniques.

Groundwater Pump and Treat

A horizontal well is in contact with a larger area of soil or groundwater and therefore can treat a larger mass of contaminates. Since only one submersible pump is needed in a horizontal well system compared to typically 5 or more pumps in a comparable system of vertical wells, savings can be realized in both up-front capital costs and long-term operation and maintenance costs

See Illustrations Below

Enhanced Bioremediation

This technology injects air, nutrients or other amendments into the contaminated zone, to stimulate microbial growth and promote the degradation of contaminants. The increased surface area provided by horizontal wells allows for more efficient delivery and distribution of amendments as compared to vertical wells. Increased surface area is of particular advantage in diffusion-driven delivery of some bioamendment materials.

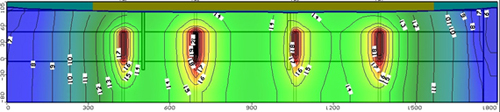

Air Sparging and Soil Vapor Extraction (SVE)

In this technology air is introduced below the water table to enhance not only bioremediation but also volatilization of contaminants. It will remove dissolved and adsorbed contaminants from the saturated and vadose zones. Groundwater is not removed to the surface for treatment.

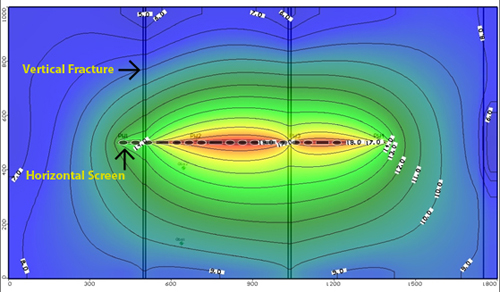

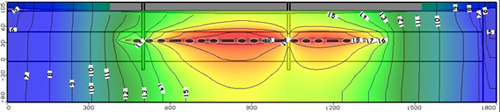

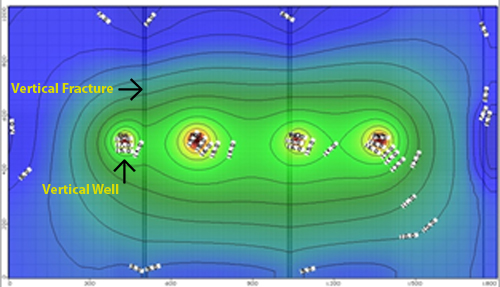

In general, this technology employs two parallel wells—one below the water table to inject air and one above the water table to extract vapors. Due to the long screened interval (increased surface area) and linear configuration horizontal wells more effectively distribute air into and extract vapors from the contaminated area.

Success stories using this approach have been reported for releases at airports impacted with jet fuel, petroleum terminals, refineries and pipelines. In all of these cases the impacted media consisted of soils and groundwater with dissolved and adsorbed constituents, and with free product. This approach can successfully mitigate a plume of contamination flowing off-site, protecting down-gradient neighbors.

In an article entitled “Horizontal Biosparge Wells Treat Petroleum Free Product (Horizontal News Volume 8/Number 1, Fall 2005) Louis B. Fournier, PhD reported that a typical vertical sparge well will have a radius of influence of less than 20’ around the well. Whereas, horizontal sparge wells will typically have a radius of influence of 100’ on each side of the well. For this reason a horizontal well will introduce far more air into the subsurface than a vertical sparge well. Similarly, this results in greater removal of contaminants via SVE.

Additionally, according to Dr. Fournier, if free product is present, the use of vertical sparge wells can “push” the separate phase product away from the wells. EPA guidance suggests that the presence of separate phase petroleum may prevent vertical sparge wells from cleaning up a contaminated site due to the migration of product away from the vertical well. While there is migration of free product away from a horizontal well it must travel much further to get out of the treatment zone due to the much larger zone of influence. Horizontal biosparge wells can be designed to minimize mounding and keep migration under control.

In many cases, the cost of environmental cleanup is lower if the system takes advantage of horizontal well technology, not only because of lower annual operation and maintenance costs, but because cleanup goals are met in less time than with a traditional vertical well system.

In summary horizontal wells have functional differences that result in improved remediation efficiencies. This can result in total project savings of 50% or more.

The company has experience in the oil field, environmental remediation industry and utility industry which allows us to complete projects that were previously considered unfeasible. The company’s personnel have been directional drilling horizontal wells since 1984! Please give us a call to further discuss the key elements of successful horizontal remediation systems.