You, as the contractor, know that adjustments in the field due to unknowns will probably have to be made even with the best drawings and specifications. Relying on a directional driller that is prepared to easily adjust their drilling plan and complete the installation with little or no downtime is crucial. This is why a directional driller that understands pipe bend and many other directional drilling factors is essential.

The Importance of Bend Radius

The following factors must be considered when planning a directional drilling for pipe installation project’s to be success:

- Bend radius

- Product diameter

- Length of the borehole

- Soil properties at the site

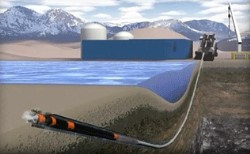

Bend radius and ground conditions are two of the most important factors to consider when installing any pipe in the ground. It is the minimum radius one can bend a pipe without kinking, this must be considered for both the product and drill pipe, which can damage, or shorten its life of both. Bend radius must be calculated for with any directional drilling pipe installation project.

During the installation of pipeline products, the pipe experiences a combination of tensile, bending, and compressive stresses. Every type of pipe has its breaking point and steering clear of damaging pipe can be accomplished if the right steps are taken. Directional Technologies researches and incorporates bend radius, along with all other important factors into every directional boring pipe installation project we do.

Choosing a Conduit Type

From time to time, Directional Technologies makes suggestions for the type of conduit to be installed based on bend radius and other factors, including site conditions, which differ from the original plan. Where a polyvinyl chloride (PVC) pipe may be best for a shallow directional installation in sand, a better choice for a deeper directional bore installation at a site with layers of silty-clay fill and sand may be High Density polyethylene (HDPE) pipe. All pipes have their place and use.

Directional Technologies’ mission is to make sure that the pipe that you put in the ground with directional drilling is the best possible long-term, most cost-efficient value for your project.

Experience Matters During Installation

Should any unknown site conditions be encountered, our drill teams have the experience and knowledge to easily adjust to changing conditions and make appropriate corrections in the field, knowing that any adjustment made should not exceed the recommended bend radius of the drill pipe and product.