If you work on contaminated sites, you’re a planner. Effective remediation starts with identifying the contaminated zones and ends with applying the correct remedial solution. Horizontal soil sampling is an invaluable tool for collecting data from inaccessible areas and filling in data gaps so that you don’t spend money in the wrong areas.

Significant Advantages When Soil Sampling

Horizontal drilling techniques offer significant advantages when soil sampling, particularly on environmental projects where contamination exists in limited-access locations. Traditional vertical drilling methods may be limited by obstacles such as buildings, infrastructure, or underground utilities, which present substantial data gaps in understanding the conceptual site model. In contrast, horizontal drilling allows for the collection of soil samples beneath structures without the need for disruptive excavation or potential damage to existing facilities. This minimizes the impact on the surrounding environment, providing a less invasive and more efficient approach.

Reduce Impact on Surface Environment

The non-disruptive nature of horizontal drilling reduces the impact on the surface environment, particularly when it is critical that on-site business operations continue as usual. This is especially important when working in urban or developed areas, where minimizing disturbance and reducing restoration costs is critical. By avoiding extensive excavation, the technique helps preserve the integrity of the surrounding landscape and structures, contributing to a more sustainable and environmentally friendly approach to soil sampling and contamination delineation.

Targeted Installation of Soil Vapor Extraction

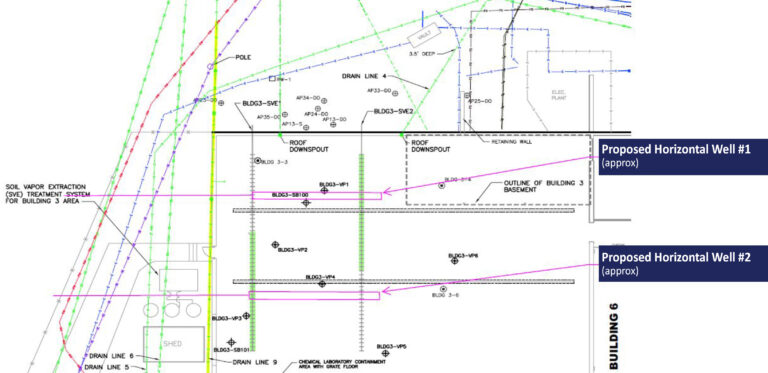

Similar to vertical soil samples, horizontal soil samples can be analyzed in the field to assess where to place screen portions of horizontal remediation wells. In the example below, two horizontal boreholes were advanced beneath an occupied warehouse. Business continued as usual as soil samples were collected every 5 feet along the length of the 200-foot-long building, at a depth of approximately 25 feet below ground surface. The samples were field screened with a photoionization detector (PID). It was discovered that contamination only existed within the first 80 feet of the building. As a result, two horizontal soil vapor extraction (SVE) wells were installed with 80 feet of screen beneath the building footprint. The ability to collect soil samples horizontally was critical to find the target zone and helped save project budget by preventing needless well installations into clean soil.

Written by: Elliott Andelman, Professional Geologist